A research team from the University of Bristol in partnership with researchers from the US Office of Naval Research has detected and measured internal friction, stress and strain shear modulus of graphene sheets for the first time.

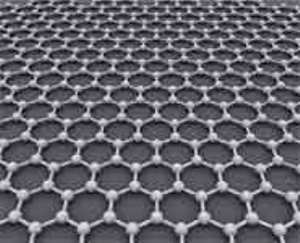

Graphene is an atomic-scale honeycomb lattice made of carbon atoms. (Image by Alexander Alus)

Graphene is an atomic-scale honeycomb lattice made of carbon atoms. (Image by Alexander Alus)

It is important to understand graphene’s structural limitations and behavior as a mechanical material for use in nanosensors or nanoelectromechanical resonators. Fabrizio Scarpa from the University of Bristol informed that the research findings show that graphene synthesized by the chemical vapor deposition (CVD) technique makes it suitable for nanomechanical sensor applications.

Using CVD technique, the research team grew graphene films over copper foil from a mixture of hydrogen and methane inside a quartz tube furnace at a temperature of 1030°C. The study discovered certain elastic properties of the single-layer, CVD-grown graphene films on copper. The findings revealed a significant difference between multi- and single-layered graphene sheets in terms of internal friction and shear modulus. This difference may be caused by the change in the shear restoring force from chemical bonding inside an interlayer to layer interactions.

The research team compared the graphene films’ average shear modulus with nearly all of the theoretical calculations built upon single-layer pristine graphene structures. The low internal friction and high shear modulus point to a minimal defect density structure nearing that of the pristine graphene. The results show that the CVD-grown graphene may be a suitable material for use in nanomechanical sensor applications.

The research findings have been reported in Nano Letters.