DuPont’s Vespel and Kalrez perfluoroelastomer parts and shapes, which are being manufactured in the two US facilities, have received Nadcap accreditation.

Vespel parts

Vespel parts

Nadcap is a certificate of excellence in the aerospace industry and will be given only if the strict technical demands are met.

Mark Forkapa, DuPont Kalrez and Vespel business’ global aerospace marketing manager commented that this Nadcap accreditation highlights the company’s commitment to the aerospace industry and the potential of the quality systems. He added that the company is investing in the field of science to offer sealing, wear and friction material solutions and in the special methods deployed in the manufacturing plants to supply customers with the parts specified by them.

The Performance Review Institute (PRI) gave accreditation to the Ohio-based facility, producing Vespel parts and shapes, and to Newark-based DuPont plant that manufactures Kalrez parts. Beforehand, these two plants received compliance certification with the AS 9100 quality systems standard of the aerospace industry.

Forkapa stated that this Ohio-based facility is the first to be accredited by Nadcap for compression molding methods.

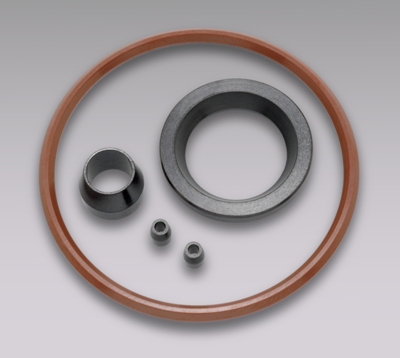

PRI accreditation was awarded to the non-metallic material testing methods of Valley View plant in Ohio. Nadcap accreditation for the Newark plant has enclosed compounding functions and Kalrez molded parts, compression seals and O-rings production.

Vespel shapes and parts are chosen by the manufacturers of airplane engines, as they combine low friction and wear, high-temperature resistance, toughness, mechanical strength and light weight. These parts can be used in applications, including external clamps, bearings and bushings compressors, and different sealing and wear elements.

Kalrez seals are used by the aerospace manufacturers to maintain high levels of recovery and elasticity, after exposing for up to 250° temperatures. They are not affected by solvents and chemicals.