An Environmentally Benign Manufacturing research team led by Tim Gutowski, a professor of mechanical engineering at the Massachusetts Institute of Technology (MIT), is working on the environmental impacts and costs associated with advanced material manufacturing.

Environmentally Benign Manufacturing group studies the life cycle of new technologies.

Environmentally Benign Manufacturing group studies the life cycle of new technologies.

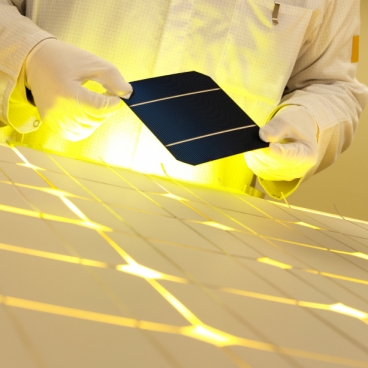

The team focuses on conventional materials like steel and concrete and advanced and developing technologies, including carbon nanotubes, photovoltaics and semiconductors. Gutowski stated that performing life-cycle analysis for traditional industries like timber production and automotive manufacturing is easy, whereas evaluating the environmental costs of newer technologies is difficult.

Carbon nanotube, one of the latest technologies, has remarkable mechanical, electrical and optical properties. The strength and flexibility of the material makes it ideal for various applications, including scaffolds for artificial muscle and bone, superconductive electrical cables and bulletproof clothing. Gutowski remarked that in order to mass produce the technology, it is essential to know the amount of energy required for the process. In 2012, MIT group has estimated the energy requirements for manufacturing carbon nanotubes. Using the data released by Rice University’s researchers that explains the conditions used for nanotube processing as well as the laws of thermodynamics. Gutowski’s group has calculated the least energy needed to drive each phase in the production process. To produce only micrograms of carbon nanotubes, a huge amount of gas has to be processed at higher pressures and temperatures.

The group has discovered that manufacturing processes for new technologies like solar panels and semiconductors are considerably less efficient than the traditional ones such as car tires and manhole covers. Researchers have revealed that advanced production techniques such as etching and vapour deposition need higher energy to process a single material unit than traditional techniques like machining and casting. In addition, the team found that manufacturing process of new technologies involve additional energy-intensive steps that do not contribute directly to the product creation. This leads to complex situations: the energy-intensive steps can generate a large amount of powerplant emissions and the newer technologies are produced at low yields. Hence, to overcome these issues, the product manufacturing needs to be analyzed from starting to end phases of its life.