A new infrared spectroscopy process has been developed by Ruhr-Universität Bochum (RUB) and Karlsruhe Institute of Technology (KIT) researchers to study the processes occurring at oxides’ surfaces. Angewandte Chemie journal published the study results.

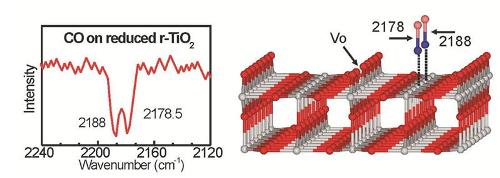

Chemistry of defects: Defect concentration on rutile surfaces of both monocrystals and powder particles can be determined by infrared spectroscopy using carbon monoxide as a probe molecule.

Chemistry of defects: Defect concentration on rutile surfaces of both monocrystals and powder particles can be determined by infrared spectroscopy using carbon monoxide as a probe molecule.

The processes at the oxide monocrystals surface were studied by the scientist team of Professor Martin Muhler from RUB and Professor Christof Wöll from KIT and applied the findings to powders, which technically are an essential form of oxide materials. Therefore the gap between applied research into real catalysts and fundamental research into reference systems was bridged by the team. The vibration frequency of carbon monoxide (CO) can be accurately measured by a new combination instrument for infrared spectroscopy (IR). The vibration frequency value is very much sensitive to defects.

Individual atoms when removed from oxide materials result in such defects. Bochum and Karlsruhe scientists used the new infrared spectroscopy combination device and developed a method, which was calibrated initially for reference systems. They measured real catalyst powders’ defect densities with the help of Bruker’s FTIR spectrometer.

Rutile is the most significant and modified form of titanium dioxide (TiO2). It is utilized by the scientists for showing the new process. Professor Christof Wöll has explained that this material used in photocatalysis and as white pigment is highly chemically inert, and turned out catalytically active through the oxygen defects. RUB’s Professor Martin Muhler has noticed that these defects found in powder materials have been identified only by indirect means.

Using this method, the scientists from RUB, which include Dr. Yuemin Wang, Dr. Heshmat Noei and Dr. Mingchun Xu, and Dr. Karin Fink from KIT’s Institute of Nanotechnology (INT), followed the Surface Science method, which was developed by Gerhard Ertl, a Nobel Prize laureate.