NUM provides in-depth engineering support and tailored CNC systems to Viewtrun Technology, a Taipei-based manufacturer of specialist machines, to enter and contend in rapidly growing Asian markets.

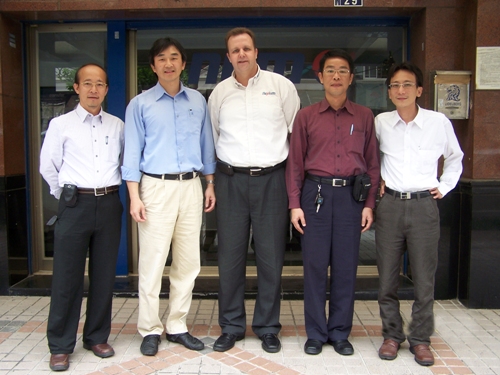

NUM and Viewtrun collaboration speeds product development. Photo shows (left to right): Yann Song, NUM Taiwan Technical Manager, Joshua Kong, Viewtrun CEO, Adrian Kiener, NUM Taiwan MD, Ivan Chen, Viewtrun Vice General Manager, and Roy Chen, Independent Consultant

NUM and Viewtrun collaboration speeds product development. Photo shows (left to right): Yann Song, NUM Taiwan Technical Manager, Joshua Kong, Viewtrun CEO, Adrian Kiener, NUM Taiwan MD, Ivan Chen, Viewtrun Vice General Manager, and Roy Chen, Independent Consultant

Viewtrun Technology develops a variety of glass finishing machines for products used in consumer electronics. These machines set new levels of performance and cost in this highly competitive automation sector. Advanced machines developed by Japanese manufacturers currently dominate this market.

Viewtrun Technology has selected to build all its machines on NUM CNC systems as it decided to collaborate with a CNC company that is ready to partner on the advancement of customized hardware and software to reduce market-reach time and add value. Another key reason is that the CNC system itself required an open architecture to offer a flexible platform for further development.

Viewtrun Technology has recently introduced its first machine, the JG-500 precision glass grinder for producers of flat panel glass-fronted displays for touch-screen devices such as tablets and smartphones. The machine automates the edge grinding process of a glass panel to take out the tiny chips formed during the cutting process of the panel. Tight working tolerances can be achieved to retain the form factor of the panel after the grinding process.

The 4-axis machine with a double spindle, the JG-500 has two linear axes, X and Z, and a vertical Y axis on which a spindle motor is mounted. All four motion axes use NUM servomotors run by MDLU digital servo drives. A NUM high-end CNC system controls the spindle motor as well as the MDLU digital servo drives. High speed interpolation methods ascertain tight positional motion control cost effectively.

NUM Taiwan developed a custom HMI that employs special parameters and functions, and uses the Chinese language for operator communication for the JG-500. The HMI connects to a parts database, which was also specially developed for the machine by NUM.

Viewtrun Technology has also devised a machine with six motion axes and two spindles called the JP-6MA to perform glass panel grinding and edge polishing. This machine is also fully controlled by a NUM advanced CNC system. At present, it is sold to particular Taiwanese customers.