OnChip Devices, a global supplier of integrated passive electronic components, has introduced the capability to design and produce custom thin film, precision resistor arrays with quick turnaround time.

Precision Resistor Array fro OnChip

Precision Resistor Array fro OnChip

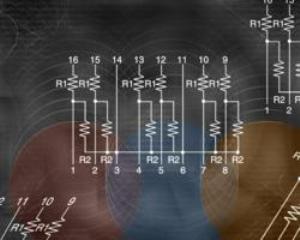

The company needs only a few weeks to convert concept to functioning product. The new capability allows customers to specify the resistor array characteristics which can comprise narrow tolerances, uncommon resistor values and intricate interconnections.

In order to obtain their custom resistor network, customers have to specify the resistor values, tolerances, special requirements for temperature co-efficient of resistance and power requirements along with the array schematic. The thin film resistors from OnChip integrate small size and characteristics such as high precision and electrical stability. The OnChip resistor arrays meet the existing demand for compact printed circuit systems that incorporate more components without compromising on reliability by integrating multiple resistors that can be trimmed using lasers on a single substrate. The customization of the resistor networks is an advantage to help counter reverse engineering of the electronic components.

The applications of custom resistor arrays are in commercial avionics, instrumentation and medical equipment. Tantalum Nitride resistor elements are moisture resistant, highly stable and self-passivating. When manufactured by employing thin-film production method, the devices perform as efficient precision voltage dividers. The applications vary from level shifting for TTL/MOS interface to voltage regulation to attenuation. The resistor arrays are assessed under rigorous military conditions stipulated for high performance electronic devices and demonstrate resistance to high temperature and thermal shock. The resistor networks are shipped as packaged products or in bare-die or wafer form. The design and manufacture is carried out at the Santa Clara facility of the company.