Apr 26 2013

Hitachi Cable, Ltd. hereby announces that it has developed a new mass-production technology for GaN-templates (Fig. 1), in which a high-quality gallium nitride (GaN) single-crystal thin film is grown on a sapphire substrate, and it will start selling these templates.

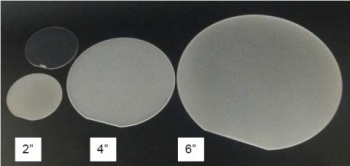

GaN-templates (Photo: Business Wire)

GaN-templates (Photo: Business Wire)

Using this product as a base substrate for an epitaxial wafer for white LEDs (hereinafter referred to as "epiwafer for white LED epiwafers") makes it possible to drastically improve productivity of white LED epiwafers and the LED properties. Therefore, this product is expected to become an effective solution to improve the position of white LED manufacturers in the industry, where there is severe competition.

The demand for white LEDs is rapidly expanding and they have come to be used in backlight unit in liquid crystal displays (LCDs) and ordinary lighting devices in recent years thanks to their energy efficiency and long service life. The structure of an white LED epiwafer consists of a thin active layer and a p-type GaN layer with a total thickness of about 1μm over an n-type GaN layer with a thickness of about 10μm, grown on a sapphire substrate (Fig. 2). All these crystal layers are produced by the MOVPE method (Note 1) in ordinary manufacturing processes. The MOVPE method is suitable for growing active layers which require atomic-level control of the film thickness. Meanwhile, a disadvantage of this method is that it takes a long time to grow a high-quality and thick n-type GaN layer. White LED epiwafers can be grown about once or twice a day at the most, and thus there is a need for a high-efficiency production method.

To solve this problem, Hitachi Cable developed a GaN-template used as a base substrate for growth in the MOVPE method.

The GaN template consists of an n-type GaN layer grown on a sapphire substrate. Using a GaN-template means LED manufacturers do not need to grow an n-type GaN buffer layer and this reduces the time required for growth by about half compared with conventional methods. The GaN-templates of Hitachi Cable are also suitable for high-output LEDs which require large currents because they allow both low resistance and high crystal formation.

Hitachi Cable has developed single-crystal free-standing GaN substrates used for blue-violet lasers and developed unique HVPE-growth (Note 2) technology and machines for mass-production of GaN substreates. Based on this technology, Hitachi Cable developed new high-efficiency production technology and machines for mass-production of high-quality GaN-templates.

The main characteristics of the GaN-template are as follows.

Main characteristics of GaN-template

- High crystal quality and high surface quality based on growth technology established in the development of free-standing GaN substrates

- Low resistance n-type GaN buffer which is suitable for high-output wafers and bonding-type LEDs (Note 3)

- Templates on flat-surface sapphire substrates and various types of PSS (Note 4) are available

- Wafers with 2 to 6 inches in diameters are available (8-inch version is now planned for development)

With this new GaN-template added to the lineup of GaN substrates and GaN epiwafers that it has been selling, Hitachi Cable will strengthen and expand its GaN product group and offer compound semiconductor products which respond to the various needs of clients.

Panel exhibits of GaN-templates will be presented at CS Mantech which will be held in New Orleans in the United States from May 13 to 16.

Notes:

- MOVPE method: metal organic vapor phase epitaxy method

- HVPE: Hydride Vapor Phase Epitaxy

- LED with electrodes on both the front and rear side made by bonding an LED epiwafer on a highly heat dissipating supporting substrate and removing the sapphire. The surface after removal of sapphire should have a low resistance in order to achieve low contact resistance.

- PSS: Patterned Sapphire Substrate; a sapphire substrate on which patterns are formed on the surface