A research team from Penn State University and Shinshu University have discovered a novel intercalation technique in the absence of an oxidizing agent for graphene manufacture, which will enable the wonder material to be produced at the industrial scale.

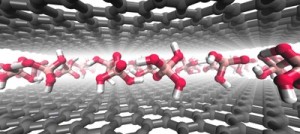

A model of the intercalation of Brønsted acid molecules between single-atomic layers of graphene Credit: Mallouk Lab, Penn State University

A model of the intercalation of Brønsted acid molecules between single-atomic layers of graphene Credit: Mallouk Lab, Penn State University

Graphene, a single carbon atom layer with excellent thermal and electrical conductivity has applications in high-speed computing, strong wind turbine blades, flexible electronic displays and more effective PV cells.

Right from its discovery, researchers have been striving to produce graphene at an industrial scale. Penn State Evan Pugh Professor of Chemistry, Physics, and Biochemistry and Molecular Biology, Thomas E. Mallouk along with scientists at the Shinshu Univerity, Japan’s Research Center for Exotic Nanocarbons have described a technique known as intercalation, which involves inserting guest molecules between graphite carbon layers to pull apart the single sheets.

In 1842, intercalation of graphite was successful; however there was always a strong reducing or oxidizing agent used that destroyed the material’s properties.

In 1999, Nina Kovtyukhova, a researcher in Mallouk’s lab developed a technique for intercalating graphite by oxidation and this method has been extensively used. Subsequently, Kovtyukhova began using an acid mixture and a strong oxidizing agent to open up single solid boron nitride layers.

Gradually, she performed the experiment without the oxidizing agents and discovered they were not required for boron nitride. She tried the same on graphite without the oxidizing agent and succeeded.

According to Mallouk, this new discovery regarding intercalation in graphene and boron nitride can apply to several other layered materials and the research team at Penn State is studying the same. Mallouk and his team are working on accelerating the intercalation reaction to ramp up production.

The research is published in Nature Chemistry.