Researchers at the Karlsruhe Institute of Technology have developed a new method for the fast manufacturing of electrode foils which enables the production of lithium-ion batteries at lower costs. The new technology increases the production speed of electrode foils by a factor of three.

Image Credit: M. Schmitt/KIT

Image Credit: M. Schmitt/KIT

The transformation of the energy system, or ‘Energiewende’, is very important and lithium-ion batteries are considered to play a significant role in this system.

An energy storage system is required for electric vehicles and fluctuating renewable energy sources but the current solutions are very expensive.

Manufacturers have been able to achieve speeds ranging from 25 to 35 metres per minute for the production of electrode foils.

The researchers at the Institute of Thermal Process Engineering at Karlsruhe Institute of Technology have developed a flexible slot die process which can increase this speed to 100 metres per minute.

This ground-breaking new coating technology was developed as part of the ‘Competence E’ project and also enables the manufacture of highly accurate patterns with high precision.

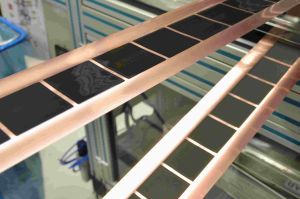

The researchers at the Karlsruhe Institute of Technology used a slurry comprised of the active material, binder, additives, solvent and carbon black and applied to this to a copper substrate foil for the anode and an aluminium substrate foil for the cathode.

To produce the electrode foil, the research team applied this slurry onto the substrate foils. Though this method enables continuous production, superior processability is achieved using intermittent coatings.

In order to achieve intermittent coatings, start and stop edges must be specifically defined and for this the researchers used a movable membrane in the coating head of the slot die. They controlled the rapid to and fro movement of this membrane to achieve highly precise intermittent patterns. Frequencies as high as 1000 electrode patterns per minute were achieved.

With this development, Karlsruhe Institute of Technology scientists have achieved the German Engineering Association’s goal of achieving 100 metres per minute coating speed by 2030.

The combination of KIT’s helix technology for manufacturing spirally wound lithium-ion batteries and the new coating technology will provide advantages in terms of cost for production of lithium-ion batteries in the future.