A team of researchers from the Universidad Carlos III de Madrid (UC3M) have discovered the way some steels fracture when they are subjected to excessive loads. Their findings will be useful to enhance these materials, which can be productively used in the automobile sector.

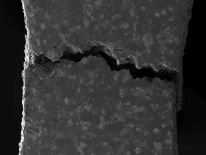

The UC3M researchers conducted their analysis using a scanning electron microscope to attain high-resolution images measuring about 10nm. They were able to use new materials characterizing processes which enabled a better comprehension of the performance of sintered steels on fracturing. In this manner, the team were able to determine where the first cracks “nucleate’’ and where they could possibly extend to.

The materials tested by them were commercial sintered steels which are manufactured using powder technology or powder metallurgy, and are very essential in the automobile sector. Mechanical and on-site characterization assessments conducted by the researchers in the scanning electron microscope have been important in clearly understanding the mechanism of fracture, which was not possible until now.

We have never been able to determine, but instead only intuit.

Elena Bernardo, from the UC3M Powder Technology Group

Many steels currently found in the market, such as Fe-C steel (steel pre-alloyed with molybdenum - Astaloy Mo grade, Höganäs AB) and Distaloy AE (Höganäs AB - iron alloyed by diffusion with copper, nickel and molybdenum) were tested.

The results from these tests have aided in formulating a connection between microstructure and properties, which are a tough technological challenge with these materials, as the phases as well as the residual porosity composing their microstructure are crucial factors.

José Manuel Torralba, full professor in the UC3M department of Materials Science and Engineering and Deputy Director of the IMDEA Materials Institute, stresses the fundamental role of porosity in these steels: “The research has revealed, among other things, that the most angular and irregular pores are the first points of ‘nucleation,’ that is, those that initiate the breaking.”

This study has made it possible to fulfill the “dream” of any scientist devoted to Materials Science and Engineering, as it makes changes in the microstructure of the material visible while it is being tested, says Torralba. Moreover, the methodology used “is applicable to any type of alloy” and not only to test its behavior under pressure, but “also its behavior at high temperatures.”

Parts of the research were performed at the UC3M facilities and were concluded at IMDEA Materials, a research institute financed by the regional government of Madrid and the European Union.

This News Featured Around the Web

References