Image Credit: The Optical Society (OSA)

Image Credit: The Optical Society (OSA)

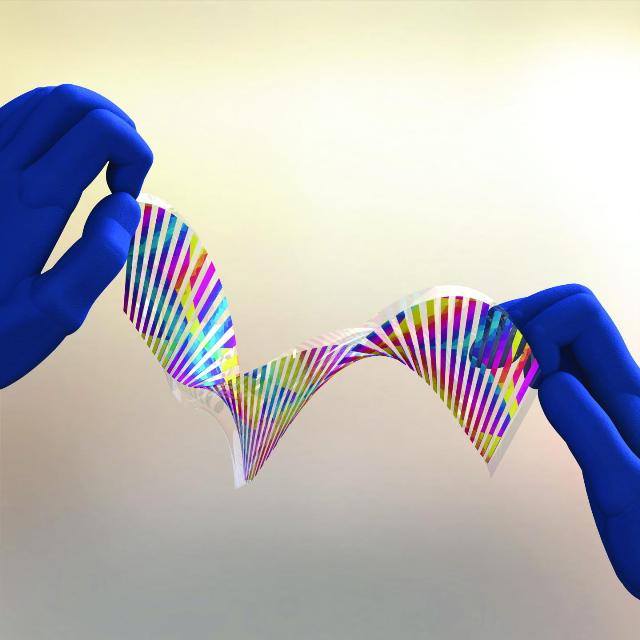

An ultrathin flexible material developed by the researchers at the University of California at Berkeley behaves as a chameleon-like skin by changing colour on demand during the application of force.

Colour-Shifting Camouflage

This new research could pave the way for the development of colour-shifting camouflage, advanced display technologies and sensors capable of determining otherwise undetectable defects in aircraft, bridges and buildings.

This is the first time anybody has made a flexible chameleon-like skin that can change color simply by flexing it.

Connie J. Chang-Hasnain, Part of the Berkeley team and Co-Author

This research follows the announcement earlier this week that a team at the University of Geneva have discovered the mechanisms which control and regulate the rapid and complex colour changes in chameleons.

Spectrum of Light

The researchers carefully etched small features that are smaller than a wavelength of light on to an ultra thin silicon film in order to create this new material-of-many-colours that allows them to choose a range of colours by flexing and bending.

The striking of white, broad spectrum light at the surface of substances such as fabrics and paints gives a specific colour to the substance based on the absorption and reflection of different wavelengths of light, depending on the chemical composition of the surface.

If shorter wavelengths are reflected back, the object will have a blue hue and the colour will be red and possible combinations of an entire rainbow colour spectrum if longer wavelengths are reflected back.

The chemical composition of the surface needs to be adjusted to change its colour. Creating designer colours without using chemical dyes and pigments is another method being explored by scientists and engineers.

Structural Colour

The surface features can be controlled on the smallest of scales instead of adjusting a material’s chemical composition, allowing them to interact and reflect only specific light wavelengths. This kind of 'structural colour' can be observed within nature on some beetles and butterflies.

Light control using structures instead of conventional optics is not a new technique and is common in astronomy, in which the use of diffraction gratings, which are evenly spaced slits, is a common practice for directing and spreading light into its component colours. However, this technique cannot be used to control light due to high optical losses.

The research team achieved colour control by employing a similar principle but with a completely different design. The researchers etched rows of ridges on to an ultra thin silicon layer rather than cutting slits into it, thus allowing reflection of a very specific light wavelength instead of dispersing the light into an entire rainbow colour spectrum..

Tuning the Colour of Light

The specific colour to be reflected can be selected by 'tuning' the spaces between the ridges. The frequency of light to be reflected was efficiently and readily reflected by the silicon bars when compared to the slits in a diffraction grating.

Since the spacing, or period, of the ridges plays a key role in the control of light they reflect, the scientists understood the possibility of subtly shifting the period and therefore the resulting colour by bending and flexing the material.

If you have a surface with very precise structures, spaced so they can interact with a specific wavelength of light, you can change its properties and how it interacts with light by changing its dimensions.

Connie J. Chang-Hasnain, Part of the Berkeley team and Co-Author

Previous attempts to make a flexible, colour shifting surface were not able to meet the requirements. Although etching metallic surfaces is easier, they were able to reflect only a part of the incident light. Other surfaces were too rigid, making them difficult to be flexed with adequate control, or had limited applications due to their thickness.

Overcoming Barriers

These barriers were successfully overcome by the Berkeley researchers by making their grating bars from a 120nm thick semiconductor layer of silicon. The silicon bars were then embedded into a flexible silicone layer in order to impart the flexibility. The period of the grating spacings shifts in response to the flexing or bending of the silicone.

Using the semiconductor material, the researchers were able to form an ultra thin, perfectly flat and easily producible skin with the desired surface properties. The resulting material is capable of reflecting up to 83% of the incident light, generating precise and very pure colours.

The research team’s original design produced brilliant colors that could be changed from green to yellow, orange, and red across a wavelength range of 39nm, when the period was changed to only 25nm.

The next step is to make this larger-scale and there are facilities already that could do so. At that point, we hope to be able to find applications in entertainment, security, and monitoring.

This is the first time anyone has achieved such a broad range of color on a one-layer, thin and flexible surface. I think it's extremely cool.

Connie J. Chang-Hasnain, Part of the Berkeley team and Co-Author

According to the scientists, future designs might be able to reflect light with much higher efficiency and cover a broader range of colours.

To demonstrate this, a 1cm2 colour-shifting silicon layer was created by the research team. However, more efforts are required to design a material having a size adequate for commercial applications.

Publication

This research has been published in the journal Optica.