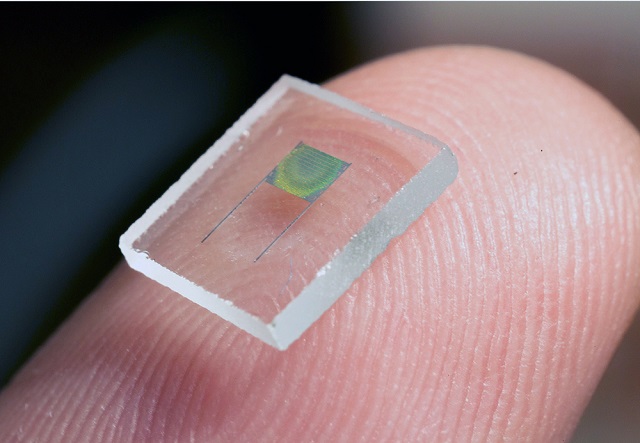

Image of the holographically patterned microbattery.

Image of the holographically patterned microbattery.

A high-performance 3D microbattery has been fabricated by a research team at the University of Illinois at Urbana-Champaign using a unique combination of 2D photolithography and 3D holographic lithography. This breakthrough device is ideally suited for on-chip integration with microelectronic devices on a large scale.

This 3D microbattery has exceptional performance and scalability, and we think it will be of importance for many applications. Micro-scale devices typically utilize power supplied off-chip because of difficulties in miniaturizing energy storage technologies. A miniaturized high-energy and high-power on-chip battery would be highly desirable for applications including autonomous microscale actuators, distributed wireless sensors and transmitters, monitors, and portable and implantable medical devices.

Paul Braun, professor of materials science and engineering (MatSE) at Illinois

“Due to the complexity of 3D electrodes, it is generally difficult to realize such batteries, let alone the possibility of on-chip integration and scaling. In this project, we developed an effective method to make high-performance 3D lithium-ion microbatteries using processes that are highly compatible with the fabrication of microelectronics,” stated Hailong Ning, a MatSE graduate student.

“We utilized 3D holographic lithography to define the interior structure of electrodes and 2D photolithography to create the desired electrode shape.” Ning added. “This work merges important concepts in fabrication, characterization, and modeling, showing that the energy and power of the microbattery are strongly related to the structural parameters of the electrodes such as size, shape, surface area, porosity, and tortuosity. A significant strength of this new method is that these parameters can be easily controlled during lithography steps, which offers unique flexibility for designing next-generation on-chip energy storage devices.”

A 3D holographic patterning technique creates desirable 3D structures through the interference of multiple optical beams within the photoresist. This helps in creating the innovative 3D microbattery consisting of well-defined, periodically structured porous electrodes. Ions and electrons are rapidly transported within the battery due to these electrodes, thus providing a power comparable to supercapacitors.

Although accurate control on the interfering optical beams is required to construct 3D holographic lithography, recent advances have significantly simplified the required optics, enabling creation of structures via a single incident beam and standard photoresist processing. This makes it highly scalable and compatible with microfabrication.

MatSE professor John Rogers

“Micro-engineered battery architectures, combined with high energy material such as tin, offer exciting new battery features including high energy capacity and good cycle lives, which provide the ability to power practical devices,” stated William King, a professor of mechanical science and engineering.

The U.S. Department of Energy, Office of Basic Energy Sciences, Division of Materials Sciences and Engineering through the Frederick Seitz Materials Research Laboratory at Illinois support this work.

Ning is the first author of the article titled, “Holographic Patterning of High Performance on-chip 3D Lithium-ion Microbatteries,” featuring in the journal, Proceedings of the National Academy of Sciences. Besides King, Rogers, and Braun, graduate students Junjie Wang, Sheng Xu, Xuejiao Li, Runyu Zhang, and James H. Pikul are the co-authors of the study.

References