Expand Application Capabilities with the OmniScan X4 128:128PR Flaw Detector

Image Credit: Evident Corporation

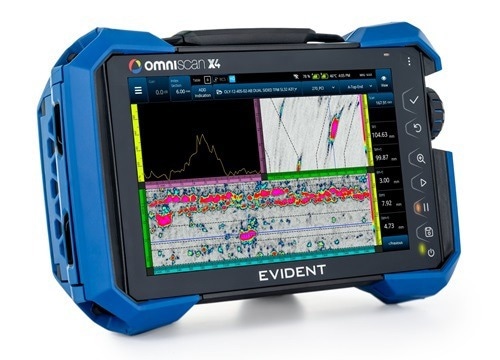

The OmniScan™ X4 128:128PR* enables the tackling of complicated tasks with confidence while remaining portable and lightweight.

- The ability to create new PAUT applications using 128-element pulsers.

- Full 128:128 power in the same portable and sturdy design.

- An upgrading path for the current OmniSca X4 64:128PR: There is no need for a full replacement

- Improved focalization and steering functionality.

- You can go beyond 64 elements for linear and matrix probes.

*Patent Pending

What the Experts Use

The OmniScan X4 flaw detector is a portable, effective new solution that increases productivity and boosts confidence through speed and versatility.

Its advanced phased array capabilities, innovative phase coherence imaging (PCI), and efficient total focusing method (TFM) enable the detection and interpretation of flaws in systems, safeguarding asset integrity by identifying damage sooner.

Proven to Perform, Trusted to Deliver

Image Credit: Evident Corporation

Each OmniScan X4 unit is a complete multitechnology inspection toolbox that allows users to employ various ultrasonic testing methods. Exploiting its advanced detection and measurement capabilities, these technologies can precisely identify and assess the extent of damage before it becomes critical, protecting the welds, parts, and assets most vulnerable to corrosion or cracking.

Assess with Certainty Using PCI

Image Credit: Evident Corporation

Eradicate uncertainty by utilizing phase coherence imaging’s ability to identify and highlight historically challenging defects, such as hook cracks and stress corrosion cracking. PCI differentiates individual flaws in groups of cracks, so inspectors can confidently categorize them accordingly.

Three Times Faster TFM Acquisition Rate

Image Credit: Evident Corporation

The enhanced processing power of the OmniScan X4 allows users to acquire clear TFM imaging at up to three times faster acquisition rates than the previous model (X3 64). Take advantage of the OmniScan X4 64:128PR and 128:128PR units’ faster speed and 128-element capacity to conduct TFM inspections with increased focusing capabilities.

Gain Instant Insights and Eliminate Inefficiency

Twice the Confidence with Twin TFM and PCI

Image Credit: Evident Corporation

PCI and TFM's distinct qualities allow users to examine the volume of welds from both sides concurrently. Dual probes can be used to scan the weld in one pass, displaying PCI and TFM results to compare, measure, and confirm indication characterization quickly and accurately.

Engineered for Speed and Simplicity

The OmniScan X4 makes performing phased array, TOFD, TFM, and PCI easy. The simple, step-by-step Scan Plan and application presets allow users of all experience levels to use these techniques confidently and efficiently.

Convenient Application Presets

Image Credit: Evident Corporation

Using the OmniScan X4 application presets helps users increase the reliability and consistency of operations. Even inexperienced users can create optimal PA or PCI configurations in just a few minutes.

These preprogrammed parameters, which include corrosion and composite inspection options, make scanning setups with HydroFORM™, FlexoFORM™, and RollerFORM™ scanners easier. Users can modify the settings as necessary.

Ease Complex Configurations

Image Credit: Evident Corporation

From the simplest to the most intricate inspection setups, the OmniScan X4 Scan Plan’s user-friendly, step-by-step 3D graphics make each process easier.

When creating a raster scan plan, users can give the scan axes custom names and create a datum reference point relative to the asset. These real-world references, combined with the true orientation correction, make it much easier to create an intuitive schematic representation of the inspection data for the report.