Jul 6 2015

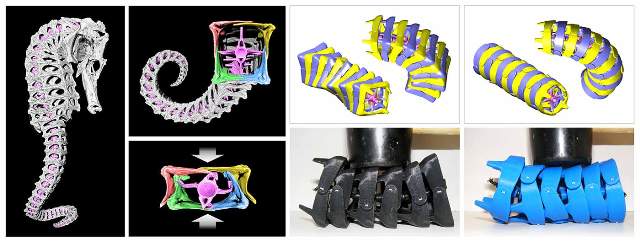

Left: seahorse skeletons are composed of highly articulated bony plates that surround a central vertebral column. Right: Bending and twisting performance of 3D printed prototypes.

Left: seahorse skeletons are composed of highly articulated bony plates that surround a central vertebral column. Right: Bending and twisting performance of 3D printed prototypes.

A team of researchers from University of California, San Diego have discovered that the squared-shaped tail of a seahorse can grasp, grip and produce more contact points with a surface compared to a cylindrical tail.

At the same time, the square plates make the tail stronger, stiffer and more resistant to strain. The tail of a seahorse has approximately 36 square-like segments, with each segment containing four L-shaped corner plates which gradually reduce in size along the tail’s length. These plates glide or turn freely. Pivoting joints are similar to ball-and-socket joints and have three degrees of rotational freedom.

Gliding joints enable the bony plates to move past one another. Thick collagen layers of connective tissue link these plates to the vertebrae. The joints between the vertebrae and plates are quite flexible with almost six degrees of freedom.

"Almost all animal tails have circular or oval cross-sections but not the seahorse’s. We wondered why. We found that the squared-shaped tails are better when both grasping and armor are needed," stated Michael Porter, the lead investigator of the study and an assistant professor in mechanical engineering at Clemson University. He earned his doctorate in materials science and engineering at the University of California, San Diego, in 2014.

According to Porter, if any one of these characteristics is strengthened, it will weaken at least one of the other characteristics. He along with other researchers set out to investigate this phenomenon. The team observed that when square plates are crushed they slide and move with just one degree of freedom. Circular plates are characterized by two degrees of freedom; they both slide and rotate. Therefore, the square plates tend to take in more energy ahead of the permanent failure.

The research group used a variety of methods, including a 3D printed square seahorse tail model, which was bent, turned, compressed and crushed. Likewise, they also designed a tail model made of round, overlapping segments which was also 3D printed to perform similar experiments.

New technologies, like 3D-printing, allow us to mimic biological designs, but also build hypothetical models of designs not found in nature. We can then test them against each other to find inspiration for new engineering applications and also explain why biological systems may have evolved.

Michael Porter, Clemson University

The study is based on the research initiated by Porter at UC San Diego in partnership with Dominique Adriaens, professor of evolutionary biology at Ghent University and Marc Meyers and Joanna McKittrick, materials science and engineering professors at UC San Diego.

"Michael decided to use engineering and technology to explain biological features," stated McKittrick, co-author of the study and Porter’s co-advisor. "You can simplify nature and study it in the lab, then you can build new bioinspired structures and devices," added Meyers, who was also Porter’s co-advisor and co-author of the paper.

At Clemson University, Porter’s research team are using this approach to design innovative robotic systems and structures that imitate a range of theoretical and other natural systems, enabling them to translate the study across multiple disciplines - from the field of biology as a basis of inspiration for engineering and from the field of engineering to explore biology further.

When the 3D printed model of the square seahorse tail was twisted, it was observed that the tail’s plates obstructed each another, thus restricting its range of movement significantly in contrast to the model composed of round segments. After the square model was twisted, it quickly returned to its original shape without using significant amount of energy. The research team hypothesized that this could possibly shield the tail from further damage.

However, while a tail with round segments twisted easily, it needed more amount of energy to come back to its original shape. It was also observed that the square segments of the tail produced more contact points in contrast to a round-segmented tail. The tail of the seahorse also bends in such a way that it can grab objects that fall within its line of sight.

Porter was assisted by Ross L. Hatton, co-author of the study, assistant professor of mechanical engineering at Oregon State University and specialist in robotics, to develop geometric prototypes, illustrating the mechanics of the tail and demonstrating that its shape is accurately designed for this type of grasping.

In addition, models with 3D printed segments were compressed and their behavior was compared to 3D-printed solid structures having circular and square cross-sections without any segments. The researchers obverted that the joints in a seahorse’s tail are located at the same precise areas where the solid structures fail upon crushing. This makes the structures to absorb more amount of energy following impact.

Additionally, in all the crushing tests, the square-shaped model surpassed the round-shaped model since square segments fail but do not alter their general shape. However, when load is applied, round segments open up and transform their shape from circular to oval. This is of major significance because the main predators of seahorses are water birds, which use their beaks to capture and crush their prey.

Additionally, Porter is studying how such bio-inspired devices can be used in real life scenarios. One option is to expand the structure to design a gripping robotic arm, which can be used in hostile conditions and another option is to reduce the structure to develop a catheter. However, immense possibilities exist, said Meyers, co-author of the study.

The study, published in 3rd July edition of the journal Science, could pave the way for improved medical devices and robots.