A team of engineers from Penn State has created a cross-linked polymer nanocomposite comprising of boron nitride nanosheets that is capable of high-voltage capacity for energy storage at high temperatures. This material is flexible and can also be photo patterned.

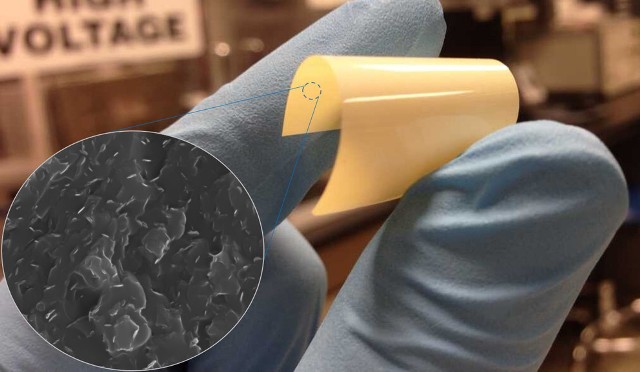

Researcher holds flexible dielectric polymer. Insert shows boron nitride nanosheets. Image: Qing Wang/Penn State

Researcher holds flexible dielectric polymer. Insert shows boron nitride nanosheets. Image: Qing Wang/Penn State

According to the Penn State engineers, these lightweight, economical, easily manufactured, flexible dielectric polymers can withstand high temperatures and could be a viable option to storing energy and power conversion in electric vehicles and several other high temperature applications.

"Ceramics are usually the choice for energy storage dielectrics for high temperature applications, but they are heavy, weight is a consideration and they are often also brittle," said Qing Wang, professor of materials science and engineering, Penn State. "Polymers have a low working temperature and so you need to add a cooling system, increasing the volume so system efficiency decreases and so does reliability."

Dielectrics are poor electric conductors that can store electricity when exposed to an electric field. They are capable of discharging energy rapidly, thus assisting engine start-ups or transforming a battery’s direct current to the alternating current required for operating motors.

Several applications, such as aerospace power electronics, hybrid and electric vehicles, and underground gas and oil exploration equipment are in need of materials that can handle high temperatures.

The boron nitride polymer composite developed by the team can handle high temperatures exceeding 480 °F under high voltage application. This material is easy to manufacture by first combining the nanosheets and the polymer. Then the polymer has to be cured using light or heat to generate crosslinks. As the nanosheets measure only around 2 nm in thickness and 400 nm in lateral size, they stay flexible. The combined material offers exceptional dielectric properties such as heat resistance, higher voltage capability and bendability.

"Our next step is to try to make this material in large scale and put it into a real application," said Wang. "Theoretically, there is no exact scalability limit."

Also working on this project were Qi Li, Lei Chen and Guangu Zhang, postdoctoral Fellows; Matthew R. Gadinski, graduate student, materials science and engineering and Long-Qing Chen, distinguished professor of materials science and engineering and professor of engineering science and mechanics; Aman Haque, professor of mechanical engineering; Tom Jackson, Robert E. Kirby Chair Professor of Electrical Engineering and Haoyu Li, graduate student in electrical engineering; and Shihai Zhang, PolyK Technologies, State College. The researchers have filed a provisional patent disclosure on this work.

The Office of Naval Research, Air Force Office of Scientific Research and Dow Chemical Corporation supported this work.

The research findings have been published in a recent issue of Nature.