Although 3D printing is growing in popularity, creating the designs is still a complicated process, with CAD expertise and hours of work required even for simple designs.

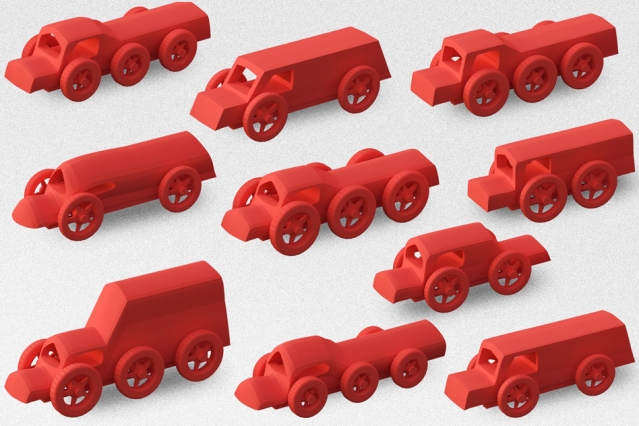

A new web-based interface for design novices allows a wide range of modifications to a basic design — such as a toy car or a black-and-white "yin-yang" cup — that are guaranteed to be both structurally stable and printable on a 3-D printer. Courtesy of the researchers (edited by MIT News)

A new web-based interface for design novices allows a wide range of modifications to a basic design — such as a toy car or a black-and-white "yin-yang" cup — that are guaranteed to be both structurally stable and printable on a 3-D printer. Courtesy of the researchers (edited by MIT News)

Researchers from MIT and Israel’s Interdisciplinary Centre Herzliya are working together to simplify the design process with the help of a new system capable of converting CAD files into visual models automatically. This system enables users to easily modify the model in real-time by moving sliders on an online page. Once the user is satisfied with the design specifications, he or she can send the design to a 3D printer by simply hitting the print button.

“We envision a world where everything you buy can potentially be customized, and technologies such as 3D printing promise that that might be cost-effective,” says Masha Shugrina, an MIT graduate student in computer science and engineering, and one of the new system’s designers. “So the question we set out to answer was, ‘How do you actually allow people to modify digital designs in a way that keeps them functional?’”

Modifying a design in CAD requires the user to change numerical input values and wait for the program to re-calculate the object’s geometry. Testing should be done using the simulation software after the design is finalized. The designs for 3D printing are tested for compliance with the specifications of the printer. In addition to this, designers test their designs for structural integrity and stability. These tests may take several minutes or sometimes several hours to complete, and the entire process needs a re-run for every single change in design.

Advance Work

A research team, including Shugrina, Wojciech Matusik – her thesis advisor and an associate professor of electrical engineering and computer science at MIT - and Ariel Shamir from IDC Herzilya, are working on simplifying visual designs so that even beginners can create designs in real time.

The new system developed by them was named “Fab Forms”, and was presented at the Association for Computing Machinery’s Siggraph Conference, which was conducted in August.

The demonstration of Fab Forms begins with a design that was originally created by a CAD expert. Further, it touches upon a wide range of parameter values of the design; these are numerical values that a CAD user usually modifies manually. The resulting geometries for different numerical values are stored by the system in a database.

The system runs a series of tests that are specified by the designer for each geometry, and stores the results. Since the entire process would span hundreds of hours if done on a single computer, the researchers distributed the process execution among several cloud servers.

A total of 8 designs were used for the experiment, which included a chess set, a coffee mug, a high-heeled shoe, and a toy car. The system tested a sufficient number of values of the design parameters to generate a reasonable approximation of all the options available. However, the number varied for each design, ranging from a few thousand, to hundreds of thousands of samples.

A smart tool devised by the team was able to spot similar design variations and thus compress the data, though the largest data set still required 17 GB of memory.

Intuitive Interface

The final step is the generation of a user interface, which is a webpage that works on all common browsers. There is a window at the center of the interface that displays the 3D model of the object. A group of sliders can be used to modify the design parameters of the object. The unwanted parameter values, which result in unstable or unprintable designs, are automatically removed by the system, confining the sliders to valid designs.

For example, to modify the width of a coffee mug’s base, one of the sliders is moved, which takes the user through visual images of the geometries associated with the move in real time. A CAD program would take hours for these calculations.

“The sample density is high enough that it looks continuous to the user,” Matusik says.

However, in a scenario where a user is looking for a parameter value that falls between two stored samples, the system can calculate the associated geometry using the CAD program, and test it out too. Though this process could take several minutes, at that stage, the user will get a reasonable idea of the final design of the object.

“Autodesk has simplified versions of this project,” says Ryan Schmidt, a senior principal research scientist and head of the Design and Fabrication Group at Autodesk Research, the research arm of the leading manufacturer of CAD software. “We have a thing called Project Shapeshifter that is very similar to what a lot of other people are doing right now, which is making these geometry generators that have a parametric model you can explore. But they all have this common problem: that you can very easily make something that won’t work on your printer. What I thought was super-exciting about this work is that it can prevent you from designing something that isn’t going to print or that isn’t going to be strong enough once you’ve printed it.”

“As soon as I saw the [Siggraph] talk, I sent it to the people who work on Shapeshifter and said, ‘You guys should have this,’” he adds. “The sliders are an interface to what they did, but the underlying technology actually has a much broader application, I think, than just this consumer product for CAD novices.”