A new method of printing rainbow holograms, most commonly used for security purposes, has been developed. The new method can be carried out using a standard desktop printer and reduces the production time from days to minutes.

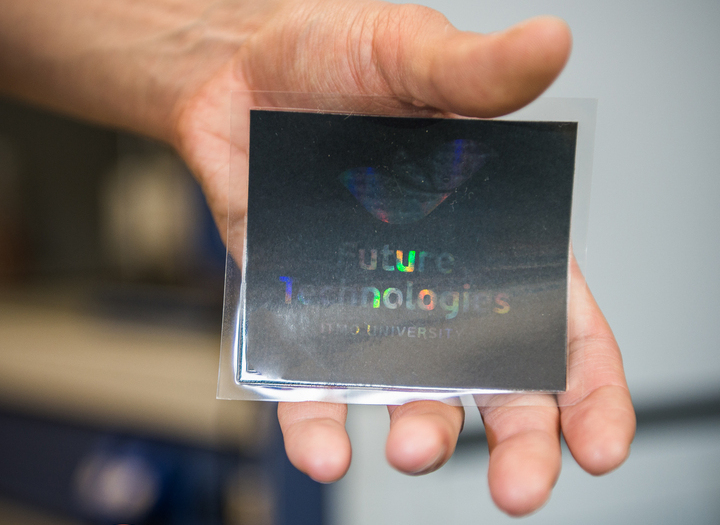

This is an example of an inkjet printed rainbow hologram. Credit: ITMO University

This is an example of an inkjet printed rainbow hologram. Credit: ITMO University

Rainbow holograms, the vivid holographic images you see on passports and credit cards, are widely used for security applications.

A team at ITMO University, led by Aleksandr Yakovlev, have developed a colorless ink produced using nanocrystalline titania which can be loaded into everyday inkjet printers. The printer can deposit the ink onto a special microembossed paper which can be used to produce unique patterned images. Conventional methods take days to print customized holographic images on transparent film; however, the new method enables printing within minutes.

Holographic imaging technology has been in existence since the 1960’s, however, many technical difficulties have affected it's integration and widespread adoption in the polygraphic industry.

The conventional way of preparing a hologram is incredibly time-consuming and consists of several stages. First of all one needs to create a master hologram, which is usually laser recorded on a thin layer of photosensitive polymer. The polymer is then dried and unexposed parts are washed out. The resulting stencil is then transferred to a metallic matrix, which eventually serves to emboss holographic microrelief on the surface of a transparent polymer film.

Aleksandr Yakovlev - ITMO

Generally, it can take several days to fully produce a holgram. Preparation of a master hologram may require even more time as it requires stricter conditions, which includes vibration isolation and temperature control.

Printing separate holographic images in a quick and effective manner is a challenge that, until now, has been unresolved

Aleksandr Yakovlev - ITMO

The innovative holographic ink enables a drastic reduction in the production cost of rainbow holograms. An ordinary inkjet printer can apply the ink on a microembossed surface and varnish can then be used to cover the printing.

The peculiarity of our ink is high refractive index in all visible range of light. The use of nanocrystalline ink forms a layer with high refractive index, which helps preserve the rainbow holographic effect after the varnish or a polymer layer is applied on top.

Aleksandr Yakovlev - ITMO

The study paper has been published in the journal Advanced Functional Materials.