Scientists at Washington State University (WSU) have created a new catalyst that is capable of changing bio-based ethanol into isobutene, an industrial chemical that is used in many applications.

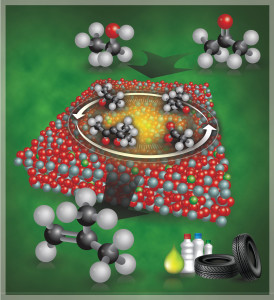

The catalyst works on bio-based ethanol to create isobutene used in plastics and other products.

The catalyst works on bio-based ethanol to create isobutene used in plastics and other products.

This latest breakthrough holds promise for developing bio-based products and plastics that are more eco-friendly. A U.S. patent has been awarded to the researchers, whose study results have been published in the Journal of the American Chemical Society.

Yong Wang, Voiland Distinguished Professor in the Gene and Linda Voiland School of Chemical Engineering and Bioengineering, explained that in order to reduce environmental impacts and adhere to recent regulations on sustainability, the chemical sector is looking for ways to switch from fossil fuels to bio-based fuels. Wang holds a joint appointment in the U.S. Department of Energy (DOE)’s Pacific Northwest National Laboratory.

In light of this, the chemical industry has developed isobutene by heating crude oil. Isobutene is used in many applications, ranging from rubber tires through to plastic soda bottles. For the study, Wang, along with other researchers, teamed up with the Archer Daniels Midland (ADM) Company to develop a catalyst that can easily change bio-based ethanol to isobutene in a single and easy manufacturing step.

This bio-based ethanol is made from a biomass such as corn. In order to determine the viability factor of the new catalyst, the team determined the lifespan and costs of the catalyst, and found that it can possibly be utilized for other similar feedstocks. The researchers also identified the unique working mechanism of the catalyst, which may help in developing advanced and highly efficient catalysts for a variety of applications.

“This is one example that shows the benefits of closely linking the practical and fundamental aspects of research to develop scalable and commercially practical catalysts for applications of importance to industries,’’ said Wang.

The study was funded by ADM along with a grant from the DOE (DE-AC05-RL01830, FWP-47319).