Feb 8 2016

Image Credit - Carlos Romero/Shutterstock.com

Image Credit - Carlos Romero/Shutterstock.com

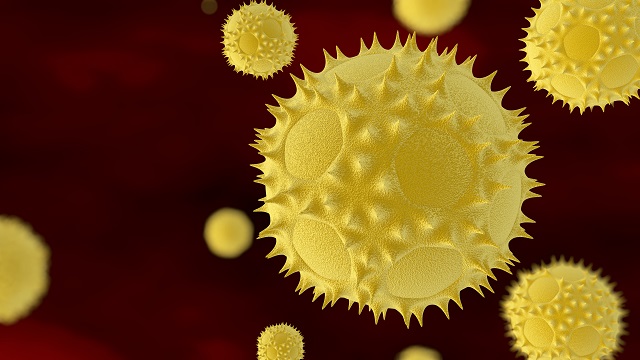

Pollens hold promise for potential application as anodes in lithium-ion batteries, according to a team of researchers from the Purdue University.

Our findings have demonstrated that renewable pollens could produce carbon architectures for anode applications in energy storage devices.

Vilas Pol, Associate Professor, School of Chemical Engineering and the School of Materials Engineering, Purdue University

Batteries are made up of two electrodes - an anode and a cathode. Most commercially available lithium-ion batteries are made of graphite anodes. Liquid electrolyte contains the lithium ions, and during recharging these ions are stored in the anode.

The Purdue team experimented with bee pollen- and cattail pollen-derived carbons for potential use as anodes.

Both are abundantly available. The bottom line here is we want to learn something from nature that could be useful in creating better batteries with renewable feedstock.

Vilas Pol, Associate Professor, School of Chemical Engineering and the School of Materials Engineering, Purdue University

The key difference between the two pollens is that the bee pollens comprise a combination of diverse pollen types gathered by honeybees, whereas the cattail pollens all possess the same shape.

I started looking into pollens when my mom told me she had developed pollen allergy symptoms about two years ago. I was fascinated by the beauty and diversity of pollen microstructures. But the idea of using them as battery anodes did not really kick in until I started working on battery research and learned more about carbonization of biomass.

Jialiang Tang, Doctoral Student

Using a method known as pyrolysis, the pollen was processed by the team at high temperatures in an argon gas filled chamber to produce pure carbon, matching the original shape of the pollen particles. In the presence of oxygen, they are "activated" by heating at a lower temperature of approximately 300°C. This causes pores to be formed in the carbon structures, increasing their capacity to store energy.

The study revealed that it was possible to charge the pollen anodes at different rates. Pol explained that it took 10 hours for a full charge to be achieved; however, charging them for just 1 hour resulted in over half of a full charge.

The theoretical capacity of graphite is 372milliamp hours per gram, and we achieved 200 milliamp hours after one hour of charging.

Vilas Pol, Associate Professor, School of Chemical Engineering and the School of Materials Engineering, Purdue University

The team simulated different environments by testing the carbon at 25°C and 50°C.

This is because the weather-based degradation of batteries is totally different in New Mexico compared to Indiana.

Vilas Pol, Associate Professor, School of Chemical Engineering and the School of Materials Engineering, Purdue University

The research discovered that cattail pollens were more successful than bee pollen. The Purdue research will continue and will be covering usage of pollen in a full-cell battery with a commercial cathode.

We are just introducing the fascinating concept here. Further work is needed to determine how practical it might be.

Vilas Pol, Associate Professor, School of Chemical Engineering and the School of Materials Engineering, Purdue University

The study was published in the February 5 issue of the Nature's Scientific Reports.

The research relating to electron microscopy was conducted at the Birck Nanotechnology Center in Purdue's Discovery Park. Purdue's School of Chemical Engineering offered its support for this study.

Funding for the electron microscopy studies at Birck was provided by a Kirk exploratory research grant, and the research was conducted by doctoral students Arthur D. Dysart and Vinodkumar Etacheri. An XPS measurement was performed at Birck by Dmitry Zemlyanov. The colored scanning electron microscope image was generated by Communications Specialist Kay J. Hagen and graduate student Jialiang Tang from the School of Chemical Engineering.

Other support was from the Hoosier Heavy Hybrid Center of Excellence (H3CoE) fellowship, funded by U.S. Department of Energy.