Apr 15 2016

Royal DSM, a global science-based company active in health, nutrition and materials, is extending its range of high temperature resistant bio-based polymers with the introduction of a new family of high performance polyamide 4T materials, partially produced from renewable resources, called ForTii® Eco. These new materials fit with the growing need of faster, thinner and more sustainable devices in the electronics industry.

On average, smart phones are getting 12% thinner every year, while speed and functionality continue to increase. At the same time there is a growing demand from society for more sustainable devices. DSM’s entire portfolio for the electronics industry is already free of halogens and red phosphorous, with materials being used in cables, connectors, frames and antennas in smart devices. It contains two materials, Arnitel® Eco (a thermoplastic elastomer) and EcoPaXX® (polyamide 410), which are partially or fully derived from renewable resources. The new ForTii Eco grades enrich the current bio-based platform, and additionally provide increased performance compared to alternative mineral oil-based solutions. DSM is introducing the new bio-based ForTii Eco grades at Chinaplas, Shanghai, April 25-28.

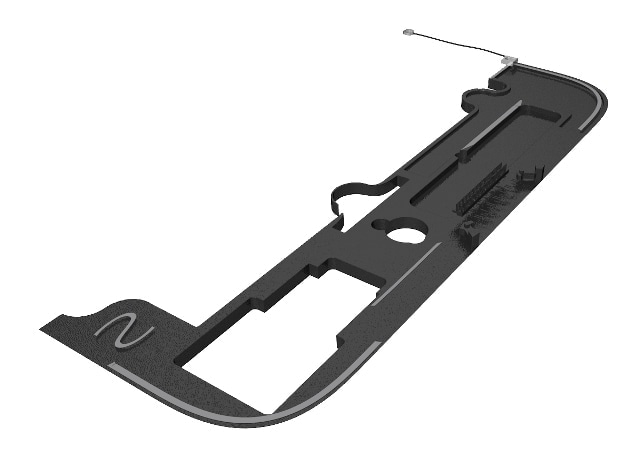

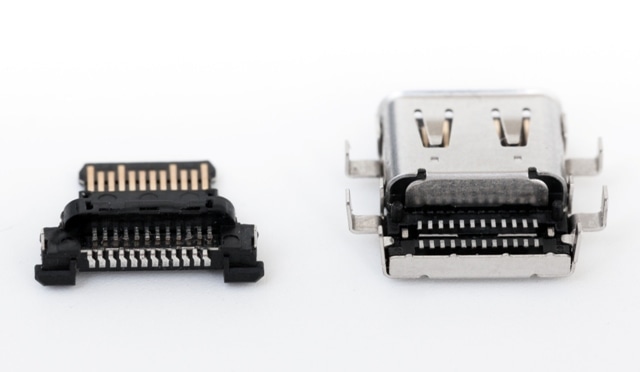

DSM ForTii® Eco grades represent the next generation of high temperature polyamides. (Photos: DSM Engineering Plastics: DSMPR479)

DSM ForTii® Eco grades represent the next generation of high temperature polyamides. (Photos: DSM Engineering Plastics: DSMPR479)

DSM ForTii Eco grades represent the next generation of high temperature polyamides. They are able to meet more stringent requirements on properties like flow, mechanical and dielectrical strength than has been possible even with “existing” ForTii grades, which already exhibit performance outperforming with other polyamides.

The polymer in the new grades is 30%-60% derived from renewable resources. DSM uses castor beans as the basis for the C10 chemistry that it incorporates. The grades have a bio-content ranging from 10% to 25% by weight on a compound basis.

The first three grades in the family are ForTii Eco E11, ForTii Eco E61 and ForTii Eco LDS62. They will provide halogen-free solutions for parts with thinner walls and demonstrate very good flow together with excellent mechanical and dielectrical properties. Key applications for ForTii Eco E11 and ForTii Eco E61 include surface-mount technology (SMT) connectors, like the new USB-C, and also audio jacks; ForTii Eco LDS62 is highly suitable for antennas, RFID security casings, and switches found in many portable electronic devices.

The ForTii Eco LDS62 grade is an ideal material especially for the production of antennas for mobile electronics, as it contains a special technology that enables incorporation of very fine and precise electrical circuitry by highly cost-effective laser direct structuring, LDS. Parts made in ForTii Eco LDS62 have very good dielectrics, good surface quality and high mechanical robustness. The total package of properties provided with this grade is superior to any other LDS grade in a competing polymer.

ForTii Eco shows low sensitivity to moisture, which ensures that its outstanding mechanical and dielectrical properties are retained even in the conditioned state. Toughness is also high. “As data transmission speeds continue to rise, there is a growing need in the market for insulating materials like ForTii that have a stable dielectric constant and loss tangent to limit signal losses,” says Konraad Dullaert, business manager ForTii.

These new grades offer higher flow and an improved processing window, combined with high toughness and full resistance to high temperature soldering. Competing semi-aromatic polyamides such as PA6T and PA10T have lower flow and lower toughness (to varying extents).

“This is an important development for processors because the new grades, with their improved processing characteristics, will help them reduce their costs while still being able to produce parts that meet OEM requirements,” says John Hsieh, marketing manager connectors. “The OEMs themselves will appreciate the marketing benefits of bio-based materials, and the ability to design thinner parts.”