Apr 21 2016

Researchers have proven that micron-scale optics can be 3D printed with exceptional performance and reproducibility. The method they used can be adapted to develop nearly any type of integrated optical element at the micron-scale or smaller, which could assist in the miniaturization of instruments and gadgets used in sensing to telecommunications applications.

Image Credit: Alexander Kirch | Shutterstock.com

Image Credit: Alexander Kirch | Shutterstock.com

The research was reported in Optica, The Optical Society's journal, where they illustrated the direct fabrication of optical elements measuring as small as 4.4 µm onto the precise center of an optical fiber just 125 µm in diameter, which is slightly thicker than the diameter of a strand of hair. They used a method known as femtosecond laser writing to achieve this complex feat, and demonstrated that the performance of the optical elements directly matched the simulations.

Although femtosecond laser writing has been demonstrated in the lab, we have shown that it can be used to make high performance micro-optics in a manner that is highly repeatable and reliable. We believe our approach can be scaled up for volume manufacturing and used to directly print almost any type of optical element on a tiny scale, opening up a new era of integrated micro- and nano-optics.

Harald Giessen, Chair for Ultrafast Nano-Optics, University of Stuttgart

Writing with light

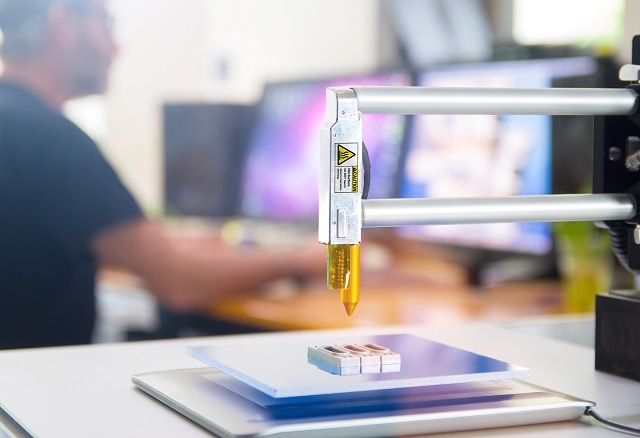

In femtosecond laser writing, a laser is used to emit very short pulses of light to selectively toughen a light-sensitive material. The material hardens just the small 3D region where the laser light is aimed, and the remaining unhardened material can be washed away, leaving behind the 3D structure that has been created.

Several labs have built their own 3D laser writing systems, but these home-made systems are susceptible to variances in laser power and environmental conditions, and cannot reliably develop superior micro-optics. To avoid these issues, the researchers used a commercially available two-photon 3D laser lithography system, designed to write structures at nanometer-scale.

The system, built by Nanoscribe GmbH, is engineered for reliability, stability, and quality.

We have something like a pen that we can move in 3D through a material to create structures in a manner similar to a 3D printer but at very tiny scales. If you punch a set of parameters into our system and into a system in some other place in the world, you will get the same exact result. Even months from now, it will come out the same every time.

Harald Giessen, Chair for Ultrafast Nano-Optics, University of Stuttgart

Creating phase masks

Using the 3D laser writing system, the researchers were able to create optical elements known as phase masks. These phase masks offer an elegant way to shape the light emitted from the end of a fiber without the need of large, heavy lenses. Light emitted out of the end of a fiber is called Gaussian, meaning it is dim towards the edges and bright at the center.

The team created the phase masks directly on the optical fiber’s end that shaped the light into either a donut-shape with an empty middle enclosed by an intense ring of light, or a flat-top outline that is equally intense across the illuminated area.

Because the phase masks are so small and are created directly on the end of the optical fiber, even tiny errors in the centering of the phase mask would cause the donut-shaped beam to not look nice and round. We solved one of the hardest problems: repeatedly placing a phase mask with submicron accuracy directly in the center of the single-mode fiber.

Harald Giessen, Chair for Ultrafast Nano-Optics, University of Stuttgart

The direct laser writing method can be applied to produce optical elements in several ways. The researchers discovered that producing phase masks ring-by-ring starting at the center or layer-by-layer from the bottom. Both options created superior structures.

Depending on how you write, you might have different optical properties, and also the velocity at which you can write and how fast you can manufacture an optical component depends strongly on your write mode.

Timo Gissibl, University of Stuttgart

The phase masks developed by the researchers offer several potential applications. By substituting large optical lenses, the top-hat phase masks possess the capacity for illumination in very small endoscopes, which are used in the medical field to observe inside the body during non-invasive procedures such as colonoscopies.

An optical fiber with the phase mask that has the capacity to create donut-shaped light, could be implemented directly in a liquid and applied for optical trapping of cells or particles. Lihong Wang, the inventor of this technology, states that photoacoustic endoscopy could profit from the highly dense hollow beam delivery.

The team is performing experiments to test whether 3D laser writing can be applied to produce tiny phase masks that shape the output of an optical fiber into twisted light. This concept holds significant interest for photon entanglement and other applications.

Now that the instrument is available, we are only limited by what we can think of to do with it.

Harald Giessen, Chair for Ultrafast Nano-Optics, University of Stuttgart