May 18 2016

Materials that react to dynamic loading can provide better protection to military convoys, reduce vibrations in vehicles, and can make buildings relatively safer during earthquakes.

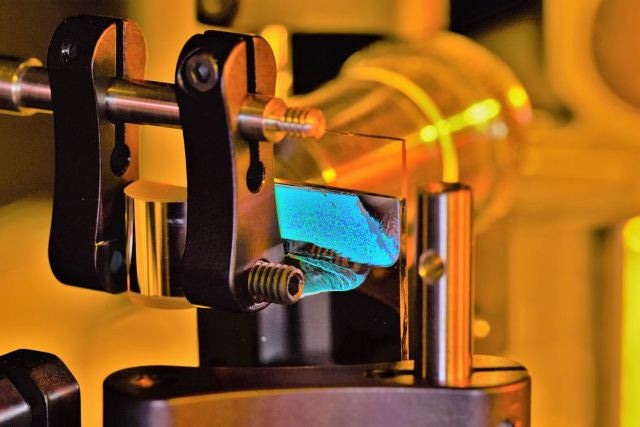

The microscale granular crystal in the laser ultrasonic experimental setup. The vibrant colors in the crystal are due to optical diffraction.University of Washington (Credit: University of Washington)

The microscale granular crystal in the laser ultrasonic experimental setup. The vibrant colors in the crystal are due to optical diffraction.University of Washington (Credit: University of Washington)

Granular materials, which are a group of particles ranging from sand to powders to tiny glass beads, interact in incredibly complicated ways, and as such are one of the least known forms of matter. However, such complex physics provide immense possibilities to develop materials with exceptional properties, such as the ability to take up impact energy in unique, customized ways.

For the first time, mechanical engineers at the University of Washington have studied collective interparticle vibrations in 2D microscale granular crystals, which are a special type of designer granular materials. The study has been reported in Physical Review Letters.

The ability and insight to predict how this microscopic range of particles behave with applied forces paves the way to produce new materials that can be employed in a wide range of applications, such as signal processing, impact mitigation, disease diagnosis, more controllable solid rocket propellants, to name a few.

A unique property of granular materials is that they are dynamically responsive, which means that these materials react in a different way when they are hit harder.

You can take a pencil and push it through a sandbag, but at the same time it can stop a bullet. So in some ways what we’re trying to do is build better sandbags in an informed way.

Nicholas Boechler, Assistant Professor of Mechanical Engineering, University of Washington

The mechanical engineering team observed that microscale granular crystals containing spheres smaller than a human blood cell have varied physical phenomena than granular materials containing larger particles. Here, adhesive forces are known to play a more critical role. As forces are applied, the range of small particles resonates in intricate patterns, knocking into one another, including the combinations of rotational and horizontal, and up-and-down movement.

This material has properties that we wouldn’t normally see in a solid material like glass or metal. You can think of it as all these different knobs we can turn to get the material to do what we want.

Morgan Hiraiwa, Mechanical Engineering Doctoral Student, University of Washington

The researchers developed the 2D ordered layer of small-sized glass spheres through self-assembly, which means countless number of particles assemble on their own into a bigger functional unit under suitable conditions. Using traditional manufacturing methods to design massive quantities of material made of tiny particles, like a panel for a vehicle, is not a viable option because this would involve a significant amount of time, said Boechler. In contrast, self-assembly provides a faster, scalable, and cheaper means to develop microstructured materials.

The researchers utilized laser ultrasonic methods to view the dynamics between tiny granular particles as they interact. This involved transmitting a laser-produced acoustic wave via the crystal and then employing a separate laser to select extremely small vibrations of the tiny particles.

While the dynamics of granular crystals containing large particles have been studied by researchers, this is the first time that such complicated dynamics have been viewed and studied in microscale crystals, which offer benefits as opposed to their larger counterparts. The small size of the microscale crystals makes it easier to incorporate them into a wide range of materials, including coatings, and they are also capable of resonating at higher frequencies, making them quite useful for signal processing and other types of applications.

The larger systems are really nice for modeling, but can be difficult to integrate into many potential products.

Nicholas Boechler, Assistant Professor of Mechanical Engineering, University of Washington

Thus far, the researchers used low-amplitude waves to carry out their experiments. Their next steps would involve exploring nonlinear, high-amplitude regimes in 3D crystals, where the granular particles move much more strongly, and may result in more interesting dynamics.

Ultimately, the goal is to use this knowledge to start designing materials with new properties. For instance, if you could design a coating that has unique impact absorbing capabilities, it could have applications ranging from spacecraft micro-meteorite shielding to improved bulletproof vests.

Nicholas Boechler, Assistant Professor of Mechanical Engineering, University of Washington

The National Science Foundation, the U.S. Army Research Office, and the University of Washington Royalty Research Foundation funded the study.

Other co-authors include Maroun Abi Ghanem, postdoctoral researcher; Amey Khanolkar and Sam Wallen, doctoral students of the UW Mechanical Engineering Department; and Alexei Maznev, research scientist of the Department of Chemistry at the Massachusetts Institute of Technology.