Aug 23 2016

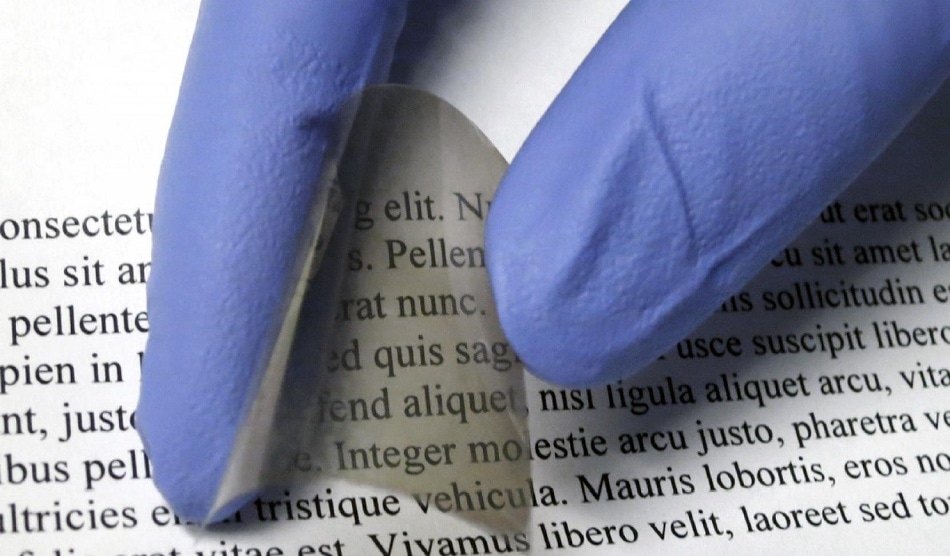

This is a darkened electrochromic film on plastic prepared by chemical condensation. (CREDIT: Cockrell School of Engineering)

This is a darkened electrochromic film on plastic prepared by chemical condensation. (CREDIT: Cockrell School of Engineering)

A new flexible smart window material has been developed by researchers in the Cockrell School of Engineering at The University of Texas at Austin. This new flexible smart material can control both light and heat generated from the sun, when it is integrated into sunroofs, windows, or even curved glass surfaces.

Their article describing the research related to the new material will be published in Nature Materials.

Delia Milliron, an associate professor in the McKetta Department of Chemical Engineering, with her research team, devised a new low-temperature coating process to coat the new smart material on plastic. This new coating technique is cheaper and easier than the conventional coating techniques that are made directly on the glass surface itself.

A flexible electrochromic device with a small electric charge of about 4 V has the potential to darken or lighten the material, and can also control the transmission of near-infrared radiations that produce heat. The main aim of this research is to reduce the money spent on paying cooling and heating bills in residential buildings and offices.

This research work involves a global collaboration of researchers from various institutions like Ikerbasque in Spain, the European Synchrotron Radiation Facility, and CNRS in France. The main theoretical work was contributed by researchers at UT Austin's College of Natural Sciences.

Milliron and her research team have devised a new low-temperature process to generate a unique nanostructured material that doubles the efficiency of the coloration process compared to the conventional high-temperature coating process. Using minimum power, it can shift between clear and tinted in a rapid pace.

Like the material that is generated by high-temperature process, the newly developed electrochromic material exhibits an amorphous structure - the atoms do not have long-range organizations like those found in a crystal.

However, a unique local arrangement of the atoms in a chain-like, linear structure is obtained from the new process. Whereas, the conventional amorphous materials that are developed at high temperature possess a denser three-dimensionally bonded structure.

The new linearly structured material is constituted of chemically condensed niobium oxide, and allows ions to flow in and out freely. It is twice as energy efficient compared to the conventionally processed smart window material.

The research team’s main focus is on the atomic-scale structure of the amorphous materials whose disordered structures are tough to analyze. As there are only limited techniques to characterize the atomic-scale structure and understand their properties, it becomes a tough task to construct amorphous materials that boost their performances.

There's relatively little insight into amorphous materials and how their properties are impacted by local structure, but we were able to characterize with enough specificity what the local arrangement of the atoms is, so that it sheds light on the differences in properties in a rational way.

Delia Milliron, Associate Professor, University of Texas

Determining the atomic structure for amorphous materials is even more difficult than analyzing crystalline materials that have an ordered structure, according to Graeme Henkelman, a co-author on the paper and chemistry professor in UT Austin's College of Natural Sciences. In this study, the researchers used a combination of techniques and measurements to analyze the atomic structure that does not vary in both theory and experiment.

Such collaborative efforts that combine complementary techniques are, in my view, the key to the rational design of new materials.

Graeme Henkelman, Chemistry Professor, University of Texas

Milliron belives that the knowledge gained in this research work will motivate deliberate engineering of amorphous materials for various other applications - e.g. for supercapacitors, which store and release electrical energy quickly and efficiently.

Development of a flexible material using a low-temperature process is Milliron lab's next challenge. This flexible material must meet or exceed the best performance of electrochromic materials that are developed using conventional high-temperature processing.

"We want to see if we can marry the best performance with this new low-temperature processing strategy," she said.