Aug 30 2016

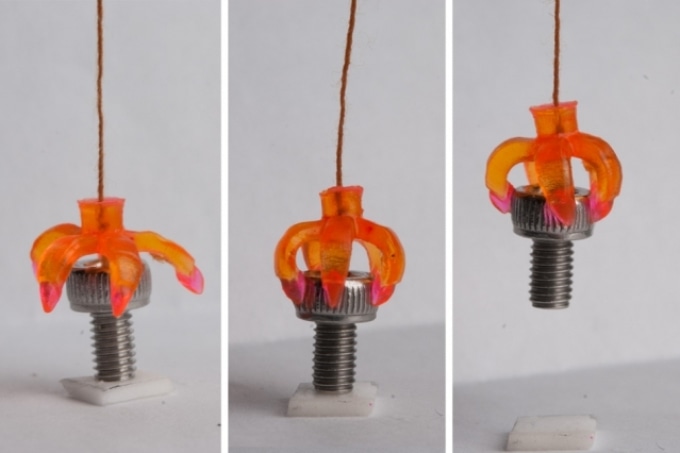

In this series, a 3-D printed multimaterial shape-memory minigripper, consisting of shape-memory hinges and adaptive touching tips, grasps a cap screw. Photo courtesy of Qi (Kevin) Ge

In this series, a 3-D printed multimaterial shape-memory minigripper, consisting of shape-memory hinges and adaptive touching tips, grasps a cap screw. Photo courtesy of Qi (Kevin) Ge

A team of engineers from MIT and Singapore University of Technology and Design (SUTD) are using light to print three-dimensional structures capable of remembering their original shapes.

The structures ranged from tiny coils and multi material flowers, to an inch-tall replica of the Eiffel tower. They were stretched, twisted and bent at intense angles, and they still rolled back to their original shapes within a few seconds after being heated to a specific temperature “sweet spot.”

For a few structures the team printed micron-scale features as tiny as the diameter of a strand of human hair. The dimensions are almost one-tenth as big as what others have been able to obtain with printable shape-memory materials.

The researchers published their findings in the recent issue of the online journal Scientific Reports.

Nicholas X. Fang, associate professor of mechanical engineering at MIT, states that shape-memory polymers that can predictably morph in response to temperature can be used for several applications, ranging from soft actuators that twist solar panels toward the sun, to small drug capsules that give way to early signs of infection.

We ultimately want to use body temperature as a trigger. If we can design these polymers properly, we may be able to form a drug delivery device that will only release medicine at the sign of a fever.

Nicholas X. Fang, Professor, MIT

Fang’s coauthors include former MIT-SUTD research fellow Qi “Kevin” Ge, now an assistant professor at SUTD; former MIT research associate Howon Lee, now an assistant professor at Rutgers University; and others from SUTD and Georgia Institute of Technology.

Ge states that the process of 3D printing shape-memory materials can also be considered as 4D printing, because the structures are designed in a manner that will change over the fourth dimension - time.

“Our method not only enables 4D printing at the micron-scale, but also suggests recipes to print shape-memory polymers that can be stretched 10 times larger than those printed by commercial 3D printers,” Ge says. “This will advance 4D printing into a wide variety of practical applications, including biomedical devices, deployable aerospace structures, and shape-changing photovoltaic solar cells.”

Image Credit: MIT

Need for Speed

Fang and other researchers have been analyzing the use of active, soft materials as pliable, reliable tools. The new materials that consist of shape-memory polymers are capable of stretching and deforming in response to environmental stimuli such as electricity, light, and heat. The applicability of these properties in artificial muscles, wearable sensors, soft robotics, and biomedical devices has been analyzed by the team.

Shape-memory polymers have their own interesting features. These materials have the potential to change between two states, a soft, high-temperature, rubbery state and harder, low-temperature, amorphous state. The shapes that are bent and stretched can be "frozen" at room temperature, and the materials "remember" and snap back to their original strong form when heated.

In an attempt to fabricate shape-memory structures, some researchers considered 3D printing as the ideal technology, allowing them to custom-design structures with moderately fine detail.

With the standard 3D printers, researchers were only able to design structures with details no smaller than a few millimeters. Fang points out that this size restriction also leaves limitations on how fast the material can regain its original form.

The reality is that, if you’re able to make it to much smaller dimensions, these materials can actually respond very quickly, within seconds. For example, a flower can release pollen in milliseconds. It can only do that because its actuation mechanisms are at the micron scale.

Nicholas X. Fang, Professor, MIT

Printing with Light

Fang and his team used microstereolithography to print shape-memory structures with finer details. Microstereolithography is a 3D printing process pioneered by the team.

Light obtained from a projector to print patterns on consecutive resin layers is used in this process.

First, the team developed a model of a structure using computer-aided design (CAD) software. This was followed by dividing the model into hundreds of slices, where each slice is sent through the projector as a bitmap, which is an image file format representing each layer as an arrangement of extremely fine pixels.

The projector now shines the light in the bitmap pattern, onto a polymer solution, or liquid resin, etching the pattern into the resin, which later solidifies.

“We’re printing with light, layer by layer,” Fang says. “It’s almost like how dentists form replicas of teeth and fill cavities, except that we’re doing it with high-resolution lenses that come from the semiconductor industry, which give us intricate parts, with dimensions comparable to the diameter of a human hair.”

The scientific literature was then taken into account by the team in order to identify an ideal mix of polymers to develop a shape-memory material on which their light patterns can be printed.

Two polymers were chosen by the team, one resembling a stiff scaffold and the other comprising of long-chain polymers, or spaghetti-like strands. After being blended together and cured, the material can be dramatically stretched and twisted without any damage.

The material also bounces back to its original printed shape with a specific temperature range between 40°C and 180°C (104°F to 356°F).

A wide range of structures printed by the team include coils, flowers, and the miniature Eiffel tower, whose full-size counterpart is recognized for its complex beam and steel patterns.

Fang discovered that the structures could be expanded without any damage for three times their original length. When exposed to heat within the range of 40°C to 180°C, the structures rolled back to their original form within a few seconds.

“Because we’re using our own printers that offer much smaller pixel size, we’re seeing much faster response, on the order of seconds,” Fang says. “If we can push to even smaller dimensions, we may also be able to push their response time, to milliseconds.”

Soft Grip

Fang and his team demonstrated a simple application for the shape-memory structures by printing a rubbery, small, claw-like gripper. They fixed a thin handle to the gripper’s base and then stretched the gripper’s claws open.

When the temperature of the surrounding air was cranked to almost 40°C, the gripper closed around whatever what place below it by the team.

The grippers are a nice example of how manipulation can be done with soft materials. We showed that it is possible to pick up a small bolt, and also even fish eggs and soft tofu. That type of soft grip is probably very unique and beneficial.

Nicholas X. Fang, Professor, MIT

Fang hopes to discover combinations of polymers in the future in order to produce shape-memory materials that respond to slightly lower temperatures, almost matching the temperature range of the human body. With this discovery, Fang plans to design controllable, active, soft drug delivery capsules.

According to Fang, this material can also be printed as responsive, soft hinges that will enable the solar panels to track the sun.

“Very often, excessive heat will build up on the back side of the solar cell, so you could use [shape-memory materials] as an actuation mechanism to tune the inclination angle of the solar cell,” Fang says. “So we think there will probably be more applications that we can demonstrate.”

This research is partially supported by the SUTD-MIT joint postdoctoral program and the SUTD Digital Manufacturing and Design Center (DManD).