Sep 2 2016

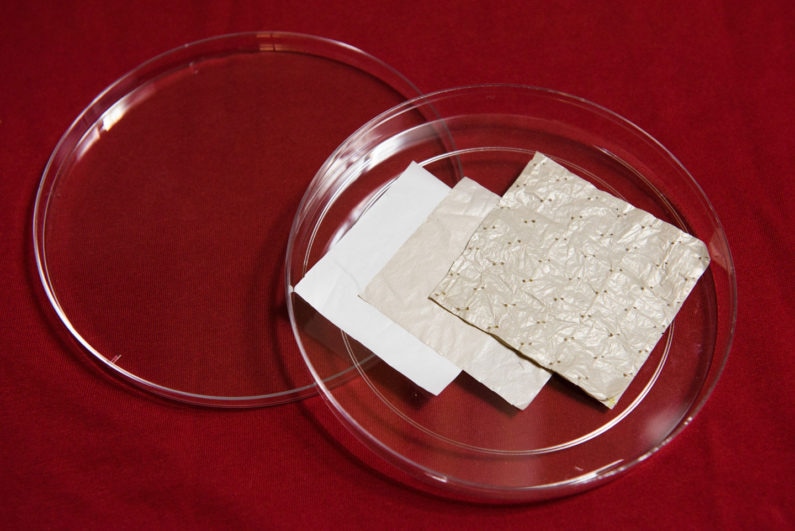

Stanford researchers began with a sheet of polyethylene and modified it with a series of chemical treatments, resulting in a cooling fabric. (Image credit: L.A. Cicero)

Stanford researchers began with a sheet of polyethylene and modified it with a series of chemical treatments, resulting in a cooling fabric. (Image credit: L.A. Cicero)

A team of Stanford engineers have created an economical, plastic-based textile with extraordinary capabilities. If this textile is woven into clothing, it can keep the body cooler than what is possible with synthetic or natural fabrics used in present day clothes.

Their research has been published in Science. The researchers believe that this new family of textiles may become the basis for garments that keep people cool in hot weather without air conditioning.

If you can cool the person rather than the building where they work or live, that will save energy.

Yi Cui, Associate Professor, Stanford University

The Stanford material makes the user feel nearly 4°F cooler than if they wore cotton clothing, by allowing the body to emit heat in two ways. By letting sweat evaporate via the material, the body is kept cool, which is something other fabrics do. However the innovative material offers a second mechanism, where heat is emitted from the body as infrared radiation to pass via the plastic textile.

Every object, including the human body, emits heat in the form of infrared radiation, which is an invisible and gentle wavelength of light. A blanket helps to keep the body warm by trapping infrared heat emissions close to the body. The thermal radiation leaving the body makes the person visible in the dark when viewed via night-vision goggles.

Forty to 60 percent of our body heat is dissipated as infrared radiation when we are sitting in an office. But until now there has been little or no research on designing the thermal radiation characteristics of textiles.

Shanhui Fan, Professor, Stanford University

Super-Powered Kitchen Wrap

The Stanford team combined photonics, chemistry, and nanotechnology to create polyethylene with several desirable features for clothing material, such as allowing thermal radiation, water vapor, and air to pass through, and remaining opaque to visible light.

The simplest feature was the ability of infrared radiation to pass through the material, which is the characteristic of basic polyethylene food wrap. However, kitchen plastic cannot be used for clothing as it is see-through and impervious to water.

The researchers handled the challenges one by one.

First, they discovered an alternative of polyethylene widely used in battery manufacture, which has a specific nanostructure that is transparent to infrared radiation but opaque to visible light.

This would potentially allow body heat to escape, and could make a base material. It was opaque to visible light to preserve modesty, but thermally transparent for energy efficiency.

They then treated the polyethylene using benign chemicals to facilitate water vapor molecules to evaporate via nanopores in the plastic, letting the plastic to breathe in the same manner as a natural fiber.

Making Clothes

The researchers had a single-sheet material that matched their three basic criteria for a cooling textile. They developed a three-ply version - two sheets of treated polyethylene divided by a cotton mesh for thickness and strength, to make the thin material feel a lot like a fabric.

To examine the cooling potential of their three-ply model against a cotton fabric with similar thickness, they placed a small piece of each material on a warm surface similar to the warmth of bare skin and measured the amount of heat each material trapped.

Wearing anything traps some heat and makes the skin warmer. If dissipating thermal radiation were our only concern, then it would be best to wear nothing.

Shanhui Fan, Professor, Stanford University

The cotton fabric made the skin surface 3.6°F warmer than the Stanford cooling textile. The researchers stated that this difference indicated that people may use less fan or air conditioner when dressed in the fabric.

Going forward, the team plan to continue their exploration on other fronts, including adding more colors, cloth-like characteristics, and textures to their material. Utilizing a material that is mass produced for the battery industry could make it easier to develop products.

If you want to make a textile, you have to be able to make huge volumes inexpensively.

Yi Cui, Associate Professor, Stanford University

Fan feels that this research will pave the way for new avenues of inquiry to passively heat or cool things, without making use of outside energy, by tweaking materials to emit or trap infrared radiation.

“In hindsight, some of what we’ve done looks very simple, but it’s because few have really been looking at engineering the radiation characteristics of textiles,” he said.

Stanford creates a plastic textile that dissipates heat

Video Credit: Stanford/Youtube.com