Sep 6 2016

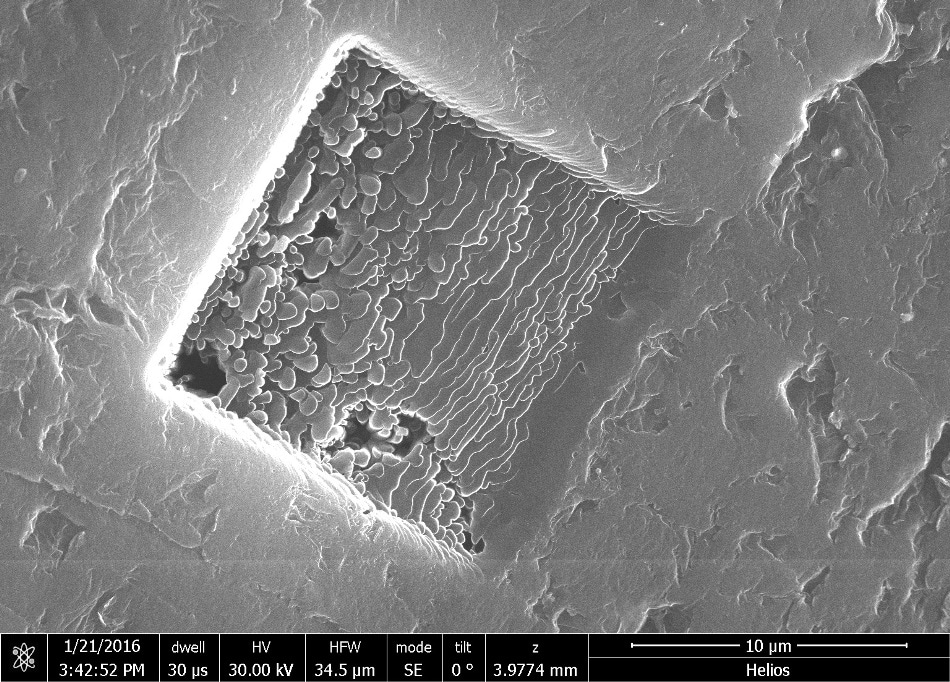

A focused ion beam microscope image shows 3D graphene layers welded together in a block. The material is biocompatible and its material properties meet the standards necessary for consideration as a bone implant, according to researchers at Rice University. Click the image for a larger version. (Courtesy of the Ajayan Group)

A focused ion beam microscope image shows 3D graphene layers welded together in a block. The material is biocompatible and its material properties meet the standards necessary for consideration as a bone implant, according to researchers at Rice University. Click the image for a larger version. (Courtesy of the Ajayan Group)

A study conducted by a team of researchers at Rice University claims that graphene flakes welded together into solid materials could be suitable for bone implants.

Rice lab materials scientist Pulickel Ajayan and colleagues in Texas, India, and Brazil welded graphene oxide flakes into porous solids using spark plasma sintering, which compare favorably with the biocompatibility and mechanical properties of titanium - a regular bone-replacement material.

The research findings have been published in Advanced Materials.

The team believes that their method will enable them to develop highly complex shapes from graphene within minutes using graphite molds, which they consider easier to process than specialty metals.

3 D graphene via spark plasma sintering

Video Credit: Rice University/Youtube.com

We started thinking about this for bone implants because graphene is one of the most intriguing materials with many possibilities and it’s generally biocompatible. Four things are important: its mechanical properties, density, porosity and biocompatibility.

Chandra Sekhar Tiwary, Postdoctoral Research Associate, Rice University

Chandra Sekhar Tiwary is co-lead author of the paper with Dibyendu Chakravarty of the International Advanced Research Center for Powder Metallurgy and New Materials in Hyderabad, India.

Tiwary explained that spark plasma sintering is utilized in industry to manufacture complex parts, usually with ceramics.

“The technique uses a high pulse current that welds the flakes together instantly. You only need high voltage, not high pressure or temperatures,” he said.

The material created by the researchers is nearly 50% porous, with a density a quarter of titanium metal and half that of graphite, but it possessed sufficient compressive strength of 40 MPa to make it eligible for bone implants.

The strength of the bonds between sheets stops it from disintegrating in water.

The researchers manipulated the material’s density by changing the voltage that supplies the highly localized blast of heat that creates the nanoscale welds. Although the experiments were conducted at room temperature, the team created graphene solids of varying densities by increasing the sintering temperatures from 200 to 400°C.

Samples created at local temperatures of 300°C turned out to be ideal, Tiwary said.

The nice thing about two-dimensional materials is that they give you a lot of surface area to connect. With graphene, you just need to overcome a small activation barrier to make very strong welds.

Chandra Sekhar Tiwary, Postdoctoral Research Associate, Rice University

Colleagues at Hysitron in Minnesota helped the researchers to measure the load-bearing capacity of thin sheets of two-to five-layer bonded graphene by continually stressing them using a picoindenter attached to a scanning electron microscope and discovered they were stable up to 70 µN.

Colleagues at the University of Texas MD Anderson Cancer Center successfully cultured cells on the material to demonstrate its biocompatibility. Another benefit the researchers discovered was that the sintering process is capable of reducing graphene oxide flakes to pure bilayer graphene, which increases their strength and makes them more stable than graphene oxide or graphene monolayers.

This example demonstrates the possible use of unconventional materials in conventional technologies. But these transitions can only be made if materials such as 2D graphene layers can be scalably made into 3D solids with appropriate density and strength. Engineering junctions and strong interfaces between nanoscale building blocks is the biggest challenge in achieving such goals, but in this case, spark plasma sintering seems to be effective in joining graphene sheets to produce strong 3D solids.

Pulickel Ajayan, Materials Scientist, Rice University

Co-authors of the paper are graduate student Sruthi Radhakrishnan of Rice and at MD Anderson; researcher Soumya Vinod and graduate student Sehmus Ozden of Rice; Pedro Alves da Silva of the State University of Campinas, Brazil, and the Federal University of ABC, Santo Andre, Brazil; Autreto Cristano Woellner and Professor Douglas Galvão of the State University of Campinas, Brazil; Sanjit Bhowmick and Syed Asif of Hysitron Inc. of Minneapolis; and Sendurai Mani of MD Anderson. Ajayan is chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry.

The research received supported from the Department of Defense, the U.S. Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative, the Sao Paulo Research Foundation, the Center for Computational Engineering and Sciences at Unicamp, Brazil, and the Government of India Department of Science and Technology.