Dec 6 2016

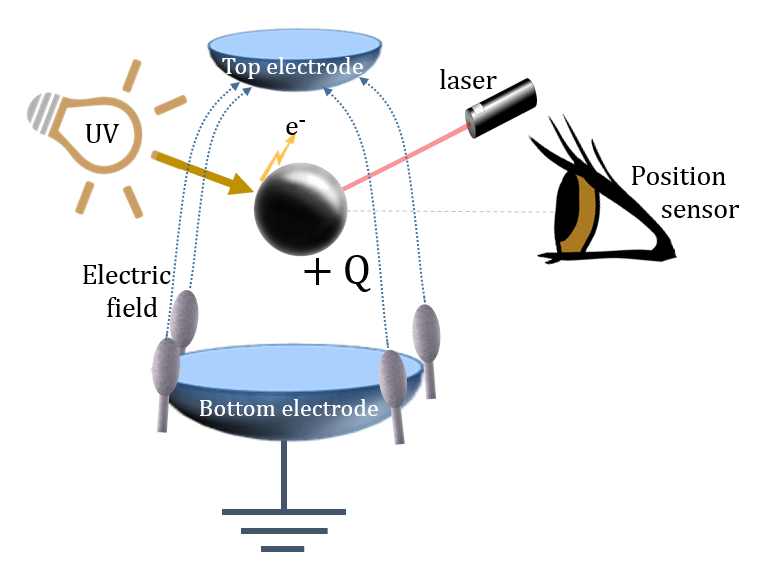

Principle of electrostatic levitation. The metal is ionized by the UV source, giving it an electrical charge enabling levitation in between the electrodes. The laser melts the metal. Using a position detector and control system, the liquid is kept in place. The new project will involve electromagnetic instead of electrostatic levitation. (Credit: University of Twente)

Principle of electrostatic levitation. The metal is ionized by the UV source, giving it an electrical charge enabling levitation in between the electrodes. The laser melts the metal. Using a position detector and control system, the liquid is kept in place. The new project will involve electromagnetic instead of electrostatic levitation. (Credit: University of Twente)

Superior quality crystals are produced when they do not experience mechanical stress during their growth. Levitating the liquid metal is the idea behind a new project headed by the University of Twente (UT).

In the project ‘Perfecting Metal Crystals,’ the UT researchers wanted to grow crystals using a metal melt, which is levitated by an electromagnetic field under vacuum conditions. The liquid is no longer held within a container and is not mechanically stressed by the container walls. According to the researchers, this process enables crystal defects caused by stress to be kept to a minimum. Crystals with superior properties can be used, for instance, in the semiconductor industry or synchrotron applications.

The research project will be carried out in close partnership with Surface Preparation Laboratory (SPL), a Dutch company established by former UT scientist Raoul van Gastel. SPL is a key provider of crystal surfaces of very high quality.

Contamination

In a typical crystal growth technique, the metal is melted inside a container, followed by introducing a lower temperature stick with a seed crystal and subsequently pulling it out of the container. This process leads to crystal growth, but is affected by stress and contamination of the container wall surface. Due to this, the resulting crystals may have carbon, says Dr Arie van Houselt of the Physics of Interfaces and Nanomaterials group (UT’s MESA+ Institute for Nanotechnology).

Although the process of growing crystals by levitating liquid metal holds potential, placing the liquid in place is a technically challenging task. With the formation of seed crystal within the liquid, the entire crystal is created that can be removed from the vacuum system completely.

In the absence of any wall stressing, will crystals at ultra-high vacuum and very clean lead to superior quality crystals as expected? The UT researchers will use a whole range of method such as atomic force microscopy (AFM) and low energy electron microscopy (LEEM) to characterize the resultant crystals. Their partners at the University of Leiden will explore the chemical properties of the newly formed crystals.

Dutch Technology Foundation STW provides funding of 0.5 million euros to the project ‘Perfecting Metal Crystals’ for a period of four years. Two PhDs will work on this project in close cooperation with the SPL company.