Dec 21 2016

Bone tissue regeneration, one of the issues of tissue engineering, is a research area for Dmitri Gorin and his international colleagues, a leading research fellow at the RASA Center in Tomsk Polytechnic University. The scientists have developed a new vaterite-based coating for nanofiber material used as a scaffold to grow bone tissue cells in a shorter time.

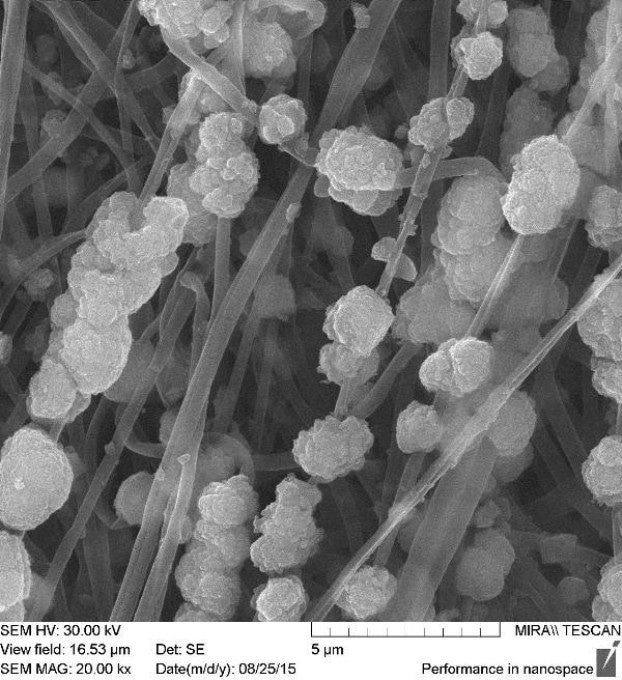

SEM image of PCL scaffolds mineralized by one treatment stage (Credit: Tomsk Polytechnic University)

SEM image of PCL scaffolds mineralized by one treatment stage (Credit: Tomsk Polytechnic University)

The process of porous calcium carbonate (CaCO3) covering on electrospun poly(ε-caprolactone) (PCL) fibers was described in this study. The cytocompatibility test shown the suitability of PCL/CaCO3 scaffolds for cell culturing.

The scientists have non-woven PCL (poly (e-caprolactone) fiber by an electrospinning technique. This technology was first developed in the USSR in the 30s last century, but it has long been classified. Then it was discovered again in the US. In regenerative medicine, nonwoven materials fabricated by an electrospinning technique can be successfully used as scaffolds for tissue engineering materials because of their unique physical chemical properties due to their nanostructured nature.

“We published the work opening new possibilities for creating scaffolds for bone growth, and in this respect it is really new and original. The work’s feature is that we had a well-known of polycaprolactone matrix, and have grown on the surface of its nanofiber a coating out of one of the polymorphic calcium carbonate modifications (CaCO3) - vaterite – a very interesting material in terms of drug delivery (since it has a porous structure ). Furthermore, in the body under certain conditions vaterite may recrystallize in bone components. Therefore vaterite / PCL composite is a promising material for bone implants,” says the study’s co-author, DSc. Dmitry Gorin, a leading researcher of the Novel Dosage Laboratory of RASA Center at TPU, and Professor of Saratov State University.

In nature vaterite is a very rare mineral due to the fact that its structure is unstable under the conditions of the Earth's surface. Vaterite has two much more common counterparts with the same chemical formula (CaCO3): aragonite and the most commonly occurring calcite. These phenomena - the existence of substances with the chemical formula but different crystal structure types - are known as “polymorphism” in mineralogy.

In order cells begin to grow, they need a basis. The basis can be different: you have to pick up the one which properties ensure the rapid growth of cells, and therefore faster regeneration of tissues. This material must meet certain requirements as the permeability of medium for various substances and water vapor permeability. After transplantation scaffolds trigger cell growth process, and then degrade. According to Dmitry Gorin, when it deals building a future bone tissue, in this case, the composite basis degradation will go slowly enough, about a month or more, which is enough to substitute the implant with the newly-formed bone tissue.

The basis is a nanostructured polycaprolactone PCL matrix, wherein the fibers surface was deposited precipitated with polycrystalline vaterite aggregates (CaCO3), which upon recrystallization in the body is transformed into hydroxyapatite (Ca5 (PO4) 3 (OH)) – a mineral, of which the human skeleton consists. This transformation is possible due to the interaction of the implant with blood and other body fluids. If blood is considered from the standpoint of ion composition, it contains a phosphate ion (PO4) 3- (in a phosphate buffer system). It is this phosphate ion reacts with coating vaterite particles, thereby recrystallizing the reaction to form hydroxyapatite. The mechanism of vaterite recrystallization process in the hydroxyapatite has been reviewed in detail by scientists in their previous work.

“Bone implants are relevant when it comes to a defect in a bone, which can’t recover itself. Now we are working on the creation of the bone implants, together with colleagues from Saratov Scientific Research Institute of Traumatology and Orthopedics,” said Dmitry Gorin.

PCL fibers obtained as mentioned above, by electrospinning. The method is that under pressure the polymer solution is fed through the needle and due to the potential difference applied between the second electrode and the needle, the thread is formed with a submicron diameter. The thread falls freely onto the substrate, which is the second electrode, and forms a non-woven fabric.

The obtained threads can be directed, but for the tasks described in the article they were to be arranged randomly. Modern membrane materials used in cloth manufacturing are permeable to steam but do not to water, and made by the same technology.

Later the researchers plan to study the behavior of the new implant material in vivo in order to investigate the possibility of using this material for regeneration of bone tissue.