Mar 13 2017

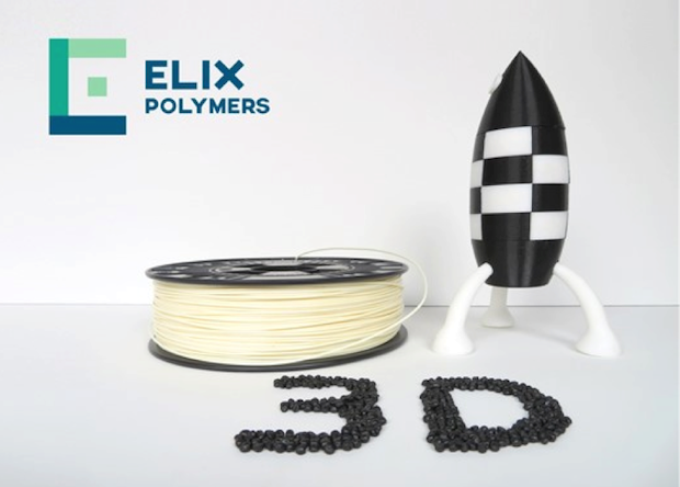

Spanish manufacturer of ABS resins, ELIX Polymers is expanding its portfolio with additional grades specifically optimised for 3D printing applications.

Credit: ELIX Polymers

Credit: ELIX Polymers

Working alongside customers to address their specific application needs, ELIX will offer a new line of 3D printing grade materials, some of which have already been validated by filament manufacturers, 3D printer makers and final part manufacturers who use FFF.

Commenting on the company’s visit to K 2016 in October which highlighted a clear demand from the 3D industry, Fabian Herter, Industry Manager Automotive, said: “We got an improved idea of the high potential growth rates of the 3D printing market during the show. We think ELIX can be an important player in this exciting market. 3D printing fits well with our strategy of focusing in specialty businesses with tailor-made products and services.”

With 40 years in the polymer industry, ELIX is applying its experience to develop a more sustainable portfolio and the company believes 3D printing has the potential to make a significant impact. Herter added: “3D printing technology can cut costs and time in development, a more efficient use of materials is possible, and final products can be customised to make them fitter for purpose."

So far, ELIX has optimised six grades of ABS available in natural or pre-coloured in various shades, each delivering improved printing performance, low warpage, dimensional precision and high resolution. The portfolio includes a general purpose grade (ELIX ABS-3D GP), one that is compatible with food contact and medical applications (ELIX ABS-3D FC), a high impact grade (ELIX ABS-3D HI), another for improved interlayer adhesion for complex parts (ELIX ABS-3D LA), and an ABS reinforced with natural fibres that produces a wood-like appearance (ELIX ABS-3D NF).

ELIX intends to supervise the complete 3D printing value chain by collaborating with several leading machine manufacturers and 3D software providers.

Antonio Prunera, Head of Quality Business Development commented: “The scope is not only to develop new formulations, but also to identify the right partners and create a database with validated filament producers.”