Mar 15 2017

While I never participated, I remember students in my high school’s more advanced science classes working together for the egg drop challenge, where teams built a container that would hold the egg during the drop and cushion it as best it could – the goal was to complete the drop without having the egg break. These days, we are seeing more school-related projects and lessons that utilize 3D printing technology, like middle school students 3D printing a bat house, or students 3D printing prosthetic hands to donate to e-NABLE. We recently learned about a project that Grayson Galisky, a senior at Los Alamitos High School in California, is working on, to develop a 3D printed biomimetic robotic prosthetic hand. Galisky is the project lead and, as evidenced by his blog, is no stranger to 3D printing for school projects, utilizing the technology in his art history class to 3D print a model of the St. Petersburg basilica, and leading a team of Boy Scouts to build a delta-style 3D printer for the local middle school for his Eagle Scout project.

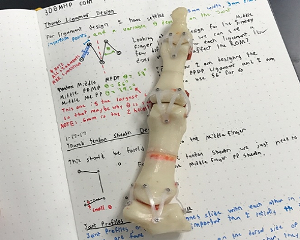

Almost fully assembled thumb. It is missing tendon sheaths. (Credit: 3D Printing)

Almost fully assembled thumb. It is missing tendon sheaths. (Credit: 3D Printing)

Galisky explains that he and his team, all high school seniors, have been working on the project in their spare time since August 2016. He notes that their work is based off of a University of Washington research paper, and that while he did in fact modify some of the design elements, “credit is due to the brilliant researchers.”

The paper, “Design of a Highly Biomimetic Anthropomorphic Robotic Hand towards Artificial Limb Regeneration,” was co-authored by Emanuel Todorov and Zhe Xu, whose work with 3D printing and robotics we are familiar with.

The paper’s abstract states, “A wide range of research areas, from telemanipulation in robotics to limb regeneration in tissue engineering, could benefit from an anthropomorphic robotic hand that mimics the salient features of the human hand. The challenges of designing such a robotic hand are mainly resulted from our limited understanding of the human hand from engineering point of view and our ability to replicate the important biomechanical features with conventional mechanical design. We believe that the biomechanics of human hand is an essential component of the hand dexterity and can be replicated with highly biomimetic design.”

Galisky’s robotic prosthetic hand is made up of 3D printed bones, tendon sheaths, ligaments, and supporting structures, such as the palm of the hand and servo tower mounting pieces, all of which were developed using both flexible and rigid materials. Galisky himself designed 37 of the project’s 57 3D files; the remaining 20 are modified bone files from Thingiverse.

There are 54 STL files for the project:

- 20 bones & 20 tendon guides

- 16 ligaments

- 14 tendon sheaths

- 6 pulleys

- 2 servo mounting plates

- 1 palm & 1 carpal tunnel

Galisky says that while the bones themselves were 3D printed using ABS materials, all other parts were made from laser cut rubber and taulman3D’s PCTPE filament and blue t-glase. All of the tendons were made with Spectra deep-sea fishing line.

“My design innovates on the current state of robot hands in several ways, but the most significant is that takes advantage of biomechanics to achieve a higher level of dexterity,” Galisky told 3DPrint.com. “My design incorporates the major components of the human hand (bones, ligaments, tendons, tendon sheath, intrinsic muscle) which allows my hand to have human like movement and speed. Instead of using traditional mechanical joints, I followed the blueprint of the human hand, using printed ligaments and laser cut rubber to form a joint capsule, which has had its rewards in terms of performance and improved dexterity over traditional robot hands.”

Galisky goes on to explain that since his robotic prosthetic hand design is very similar to a real human hand, he’s able to use data that already exists to determine how to control the hand so it moves like a real one, instead of having to write code for it: he just tracks his own hand movements using draw wire sensors. He also says that since most of his design can be printed on a hobbyist 3D printer, the total cost, including motors and other parts, is able to be kept below $600, which is a major improvement in comparison to other biomimetic robotic prosthetic hands. All of the parts, available on GrabCAD, can also be 3D printed in less than five days.

“While the actual hand in my project is larger than human scale because of ease of manufacturing, the form factor of my servo motors to control the hand is very similar to the size of my forearm which is the part that the servo array is mimicking,” Galisky told 3DPrint.com. “Most robot hands are more bulky, so my design is innovative because of its smaller and more manageable form factor.”

Current project sponsors are Filastruder, Phillips Steel, and taulman3D, though Galisky says his team is in need of more; if you’re interested in becoming a project sponsor, you can contact Galisky through his blog. He says that once the project is complete, he will be making a website that’s solely dedicated to the 3D printed biomimetic robotic prosthetic hand. Galisky entered his project in the Stratasys Extreme Redesign Challenge; you can take a look at the entry video to learn more about this project:

Stratasys Extreme Redesign Entry and 3D Hubs Entry Video - Grayson Galisky