Mar 20 2017

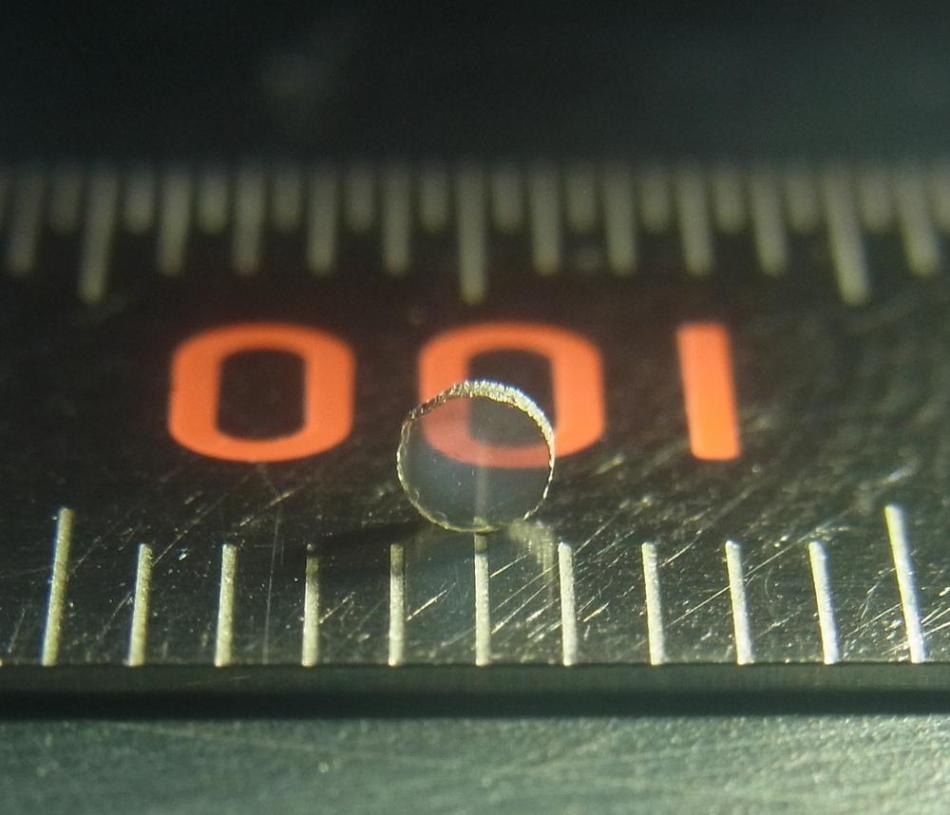

A sample of transparent polycrystalline cubic silicon nitride, synthesized at DESY. (Credit: Norimasa Nishiyama, DESY/Tokyo Tech)

A sample of transparent polycrystalline cubic silicon nitride, synthesized at DESY. (Credit: Norimasa Nishiyama, DESY/Tokyo Tech)

The first transparent sample of a well-known industrial ceramic has been synthesized by scientists at DESY. In the journal Scientific Reports, the Japanese-German team writes that the outcome is a super-hard window made of cubic silicon nitride capable of potentially being used under severe conditions like that in engines.

Cubic silicon nitride (c-Si3N4) that develops under high pressure is treated to be the second hardest transparent nanoceramic after diamond but can survive substantially higher temperatures.

Silicon nitride is a very popular ceramic in industry. It is mainly used for ball bearings, cutting tools and engine parts in automotive and aircraft industry.

Dr. Norimasa Nishiyama, DESY

Nishiyama is currently an associate professor at Tokyo Institute of Technology.

The ceramic is very stable, as the silicon nitrogen bond is extremely strong. At ambient pressures, silicon nitride consists of a hexagonal crystal structure and sintered ceramic of this phase is opaque. Sintering is the process of developing macroscopic structures from grain material using pressure and heat. The method is extensively used in industry for products ranging from ceramic bearings to artificial teeth.

At pressures of more than 130 thousand times the atmospheric pressure, silicon nitride changes into a crystal structure with cubic proportion that experts refer to as spinel-type in reference to the structure of a common gemstone. Artificial spinel (MgAl2O4) is extensively used as transparent ceramic in industry.

The cubic phase of silicon nitride was first synthesised by a research group at Technical University of Darmstadt in 1999, but knowledge of this material is very limited,” says Nishiyama.

His team used a large volume press (LVP) at DESY to subject hexagonal silicon nitride to high temperatures and pressures. At about 156 thousand times the atmospheric pressure (15.6 GPa) and a temperature of 1800 °C, a transparent piece of cubic silicon nitride was created with a diameter of approximately 2 mm. “It is the first transparent sample of this material,” emphasizes Nishiyama.

Investigation of the crystal structure at DESY's X-ray light source PETRA III revealed that the silicon nitride had totally transformed into the cubic phase.

The transformation is similar to carbon that also has a hexagonal crystal structure at ambient conditions and transforms into a transparent cubic phase called diamond at high pressures. However, the transparency of silicon nitride strongly depends on the grain boundaries. The opaqueness arises from gaps and pores between the grains.

Dr. Norimasa Nishiyama, DESY

Analysis with a scanning transmission electron microscope at the University of Tokyo revealed that the high-pressure sample has only extremely thin grain boundaries. “Also, in the high-pressure phase oxygen impurities are distributed throughout the material and do not accumulate at the grain boundaries like in the low-pressure phase. That's crucial for the transparency,” says Nishiyama.

“Cubic silicon nitride is the hardest and toughest transparent spinel ceramic ever made,” summarizes Nishiyama. The scientists predict varied industrial applications for their super-hard windows. “Cubic silicon nitride is the third hardest ceramic known, after diamond and cubic boron nitride,” explains Nishiyama. “But boron compounds are not transparent, and diamond is only stable up to approximately 750 degrees Celsius in air. Cubic silicon nitride is transparent and stable up to 1400 degrees Celsius.”

However, due to the large pressure required to synthesize transparent cubic silicon nitride, the possible window size is restricted for practical reasons.

The raw material is cheap, but to produce macroscopic transparent samples we need approximately twice the pressure as for artificial diamonds. It is relatively easy to make windows with diameters of one to five millimetres. But it will be hard to reach anything over one centimetre.

Dr. Norimasa Nishiyama, DESY

Tokyo Institute of Technology, Ehime University, the University of Bayreuth, Japanese National Institute for Materials Science, and Hirosaki University also took part in this research.

Reference:

Transparent polycrystalline cubic silicon nitride; Norimasa Nishiyama et al.; Scientific Reports, 2017; DOI: 10.1038/srep44755