Apr 17 2017

Scientists have developed a new 3D-printing technique that can be used to create everything from small tools to large buildings with dust from the Moon or Mars, an advance that could enable humans to build colonies on extraterrestrial bodies with limited surrounding resources.

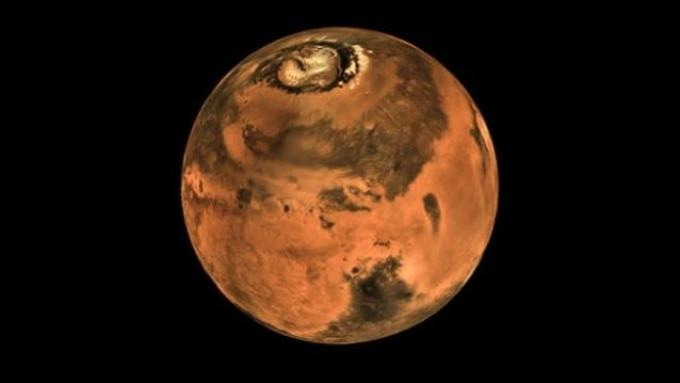

Mars, as imaged by Mangalyaan. Image: ISRO

Mars, as imaged by Mangalyaan. Image: ISRO

Researchers from the Northwestern University in the US have demonstrated the ability to 3D-print structures with simulants of Martian and lunar dust. The research uses an extension of their “3D-painting process,” which they previously employed to print hyperelastic “bone”, graphene and carbon nanotubes, and metals and alloys.

“For places like other planets and moons, where resources are limited, people would need to use what is available on that planet in order to live,” said Ramille Shah, assistant professor at Northwesterns McCormick School of Engineering. “Our 3D paints really open up the ability to print different functional or structural objects to make habitats beyond Earth,” Shah said.

Researchers used NASA-approved lunar and Martian dust simulants, which have similar compositions, particle shapes, and sizes to the dusts found on lunar and Martian surfaces. They created the lunar and Martian 3D paints using the respective dusts, a series of simple solvents, and biopolymer, then 3D printed them with a simple extrusion process. The resulting structures are over 90 percent dust by weight.

Despite being made of rigid micro-rocks, the resulting 3D-painted material is flexible, elastic and tough – similar to rubber. This is the first example of rubber-like or soft materials resulting from lunar and Martian simulant materials. The material can be cut, rolled, folded, and otherwise shaped after being 3D painted, if desired.

“We even 3D-printed interlocking bricks, similar to Legos, that can be used as building blocks,” Shah said. Researchers are working on optimising ways to fire these 3D-painted structures in a furnace, which is an optional process that can transform the soft, rubbery objects into hard, ceramic-like structures.

In the context of the broader 3D-painting technology, this work highlights the potential to use a single 3D printer on another planet to create structures from all kinds of materials, researchers said.