Jun 23 2017

A flexible thermoelectric energy harvester that has the potential to rival the efficiency of the currently available power wearable electronic devices using body heat as the only source of energy has been designed by North Carolina State University Engineers in a proof-of-concept study.

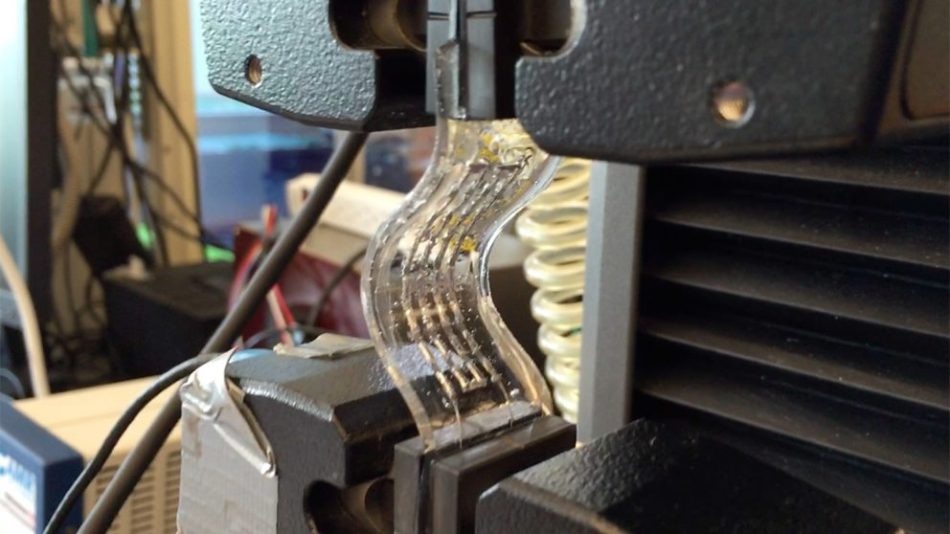

NC State's thermoelectric harvester has the material quality of rigid devices inside a flexible package. Photo courtesy of Mehmet Ozturk, NC State University.

NC State's thermoelectric harvester has the material quality of rigid devices inside a flexible package. Photo courtesy of Mehmet Ozturk, NC State University.

Presently, there is a growing popularity for wearable devices that are used to monitor different environmental and health measures. The performance and efficiency of flexible devices, however, pale in comparison to rigid devices, which have been superior in their ability to convert body heat into usable energy.

We wanted to design a flexible thermoelectric harvester that does not compromise on the material quality of rigid devices yet provides similar or better efficiency. Using rigid devices is not the best option when you consider a number of different factors.

Mehmet Ozturk, a Professor of Electrical and Computer Engineering at NC State and Corresponding Author of the Study

Ozturk mentioned greater contact resistance – or skin contact – with flexible devices, as well as the comfort and ergonomic considerations to the device wearer. Ozturk stated that he and his colleagues, Michael Dickey and Daryoosh Vashaee, planned to employ the finest thermoelectric materials used in rigid devices in a flexible package, preventing the need for Manufacturers to develop new materials when producing flexible devices.

According to Ozturk, one of the main challenges of a flexible harvester is to attach thermoelectric elements in series using low-resistivity, reliable interconnects.

We use a liquid metal of gallium and indium – a common, non-toxic alloy called EGaIn – to connect the thermoelectric‘legs'. The electric resistance of these connections is very low, which is critical since the generated power is inversely proportional to the resistance: Low resistance means more power. Using liquid metal also adds a self-healing function: If a connection is broken, the liquid metal will reconnect to make the device work efficiently again. Rigid devices are not able to heal themselves.

Mehmet Ozturk, a Professor of Electrical and Computer Engineering at NC State and Corresponding Author of the Study

Ozturk stated that future work will aim at enhancing the efficiencies of these flexible devices, by employing techniques and materials to further eradicate parasitic resistances.

The paper featured in Applied Energy was Co-Authored by Dickey, Vashaee, Francisco Suarez, Dishit P. Parekh and Collin Ladd. This group also holds a pending patent application based on the technology.

Funding for the research was obtained from the NC State’s National Science Foundation-funded Advanced Self-Powered Systems of Integrated Sensors and Technologies (ASSIST) Center under grant (EEC1160483) and from other NSF support under grants ECCS1351533 and CMMI1363485. The ASSIST Center aims at producing self-powered wearables with the potential to carry out long-term multi-modal sensing without the need for charging or replacing the batteries.