Apr 11 2018

The next-generation aircraft will fly autonomously and electrically, will be feather-light, and can be easily produced in a completely automated manner. Although the permanent autopilot and electrification are still in the inception stage, the lightweight construction has already become a prerequisite at present.

Digital manufacturing processes will be used for this purpose. Fraunhofer will introduce innovative automated production technologies for lightweight construction materials at the ILA, the largest innovation trade fair in the aerospace industry, at the Berlin ExpoCenter Airport from April 25 to 29, 2018 (Hall 2, Booth 229).

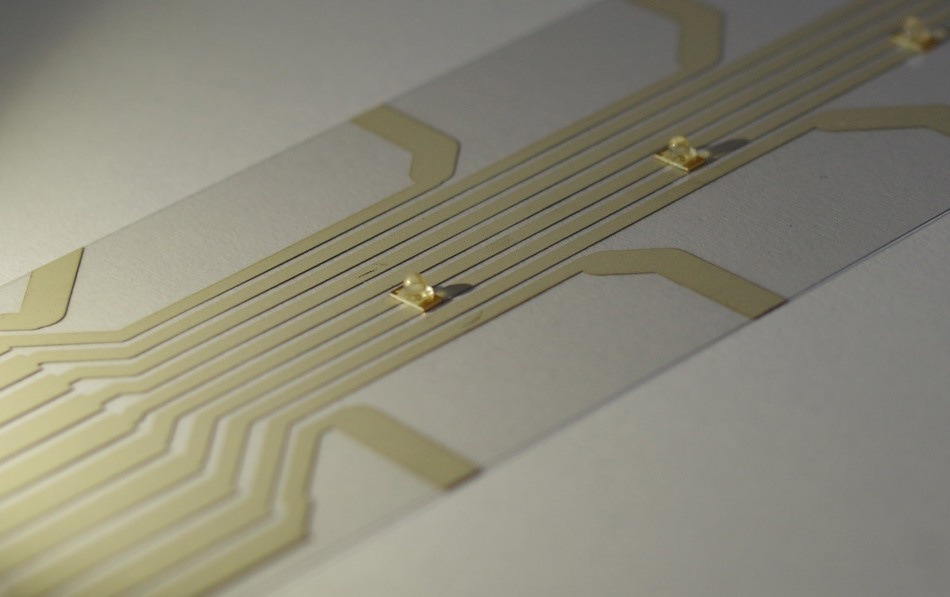

The Fraunhofer ENAS manufactures printed circuit boards in screen printing on a flexible plastic film. The tracks transmit electrical impulses—for example, to make LEDs glow. (Image credit: Fraunhofer ENAS)

The Fraunhofer ENAS manufactures printed circuit boards in screen printing on a flexible plastic film. The tracks transmit electrical impulses—for example, to make LEDs glow. (Image credit: Fraunhofer ENAS)

Similar to veins in the body of a human being, copper cables run across the fuselage of aircraft. These cables transmit electrical signals for LEDs in ceilings, temperature-measuring sensors, or electronic connections in seats. At the time of the installation, individual cables are linked into harnesses.

“The process of producing and installing cable harnesses is currently 100 percent manual. This is very time-consuming and expensive,” stated Dr. Ralf Zichner, who is the head of the Printed Functionalities department at the Fraunhofer Institute for Electronic Nano Systems ENAS in Chemnitz, Germany, and works in collaboration with his team on manufacturing processes for automatically and directly printing electrical conductors onto aircraft components.

The benefits of the processes include no waste during production, ability to adapt the print templates flexibly and quickly, and elimination of the typical laying of the cable harnesses which enables the aircraft manufacturers to save weight and space.

Printing Cable Harnesses Easily

We use electrically conductive silver ink, which we apply by screen or inkjet printing in layers of only a few microns directly onto lightweight aerospace materials, such as high temperature resistant plastics.

Dr. Ralf Zichner

Apart from using printing technologies for producing the printed conductors, the Chemnitz researchers also combined resistors, capacitors, diodes, microcontrollers, and other electronic components into aerospace modules. It is ideal to match the ink and printing processes to the materials on which the printing has to be performed. The Fraunhofer ENAS has ample expertise in these processes, specifically with regard to the aerospace requirements. The technology will be launched shortly. At present, it is being enhanced through the Fraunhofer “Go Beyond 4.0” Lighthouse Project.

Economical Production with Thermoplastics

High-temperature-resistant thermoplastics are an example of aviation-grade plastics. They are a crucial component in stable, lightweight fiber-reinforced plastics (FRP), which are vital in the construction of aircraft. It is possible to reshape or form thermoplastics in a particular temperature range; moreover, they cool down rapidly after being processed and can be processed at a high speed. Furthermore, their excellent flame resistance and the probability of functional integration make them highly impressive.

“In aviation, though, there has previously been a lack of concepts for the cost-effective production of functionally integrated thermoplastic structures,” noted Tobias Joppich of the Polymer Engineering/Thermoplastics Processing Department at the Fraunhofer Institute for Chemical Technology ICT in Pfinztal, Germany.

Working in collaboration with partners in the LuFo V-1 program, the research institute has taken a significant step forward in tapping the potential of thermoplastics for the construction of aircraft. Jointly, they have created a new component and production concept including modular stiffening elements, specifically adapted to hold cargo.

Experts in lightweight construction develop these from fiber-reinforced, high-temperature thermoplastics through a hybrid molding process, which is a combination of injection-molding and forming processes. The lightweight components are easy to assemble (they only need to be put together), can be automated in large quantities, are stable, and are flame retardant.

“This allows manufacturers to quickly stiffen interior walls of cargo holds according to a flexible design,” stated Joppich.

Then, the stable grid structure is attached to the inner wall of the cargo hold by laser transmission welding. The innovative concept from the Baden-based company can also be used for manufacturing other aircraft components, such as clips, body shell, or internal components such as seat structures. Hybrid material combinations can also be achieved by the Fraunhofer ICT.