Jun 13 2018

Sooner or later all petroleum-based material used in food packaging will have to be substituted with a bio-based material. A blend of starch and other polymers forms a similarly effective protective barrier according to a study done at Karlstad University.

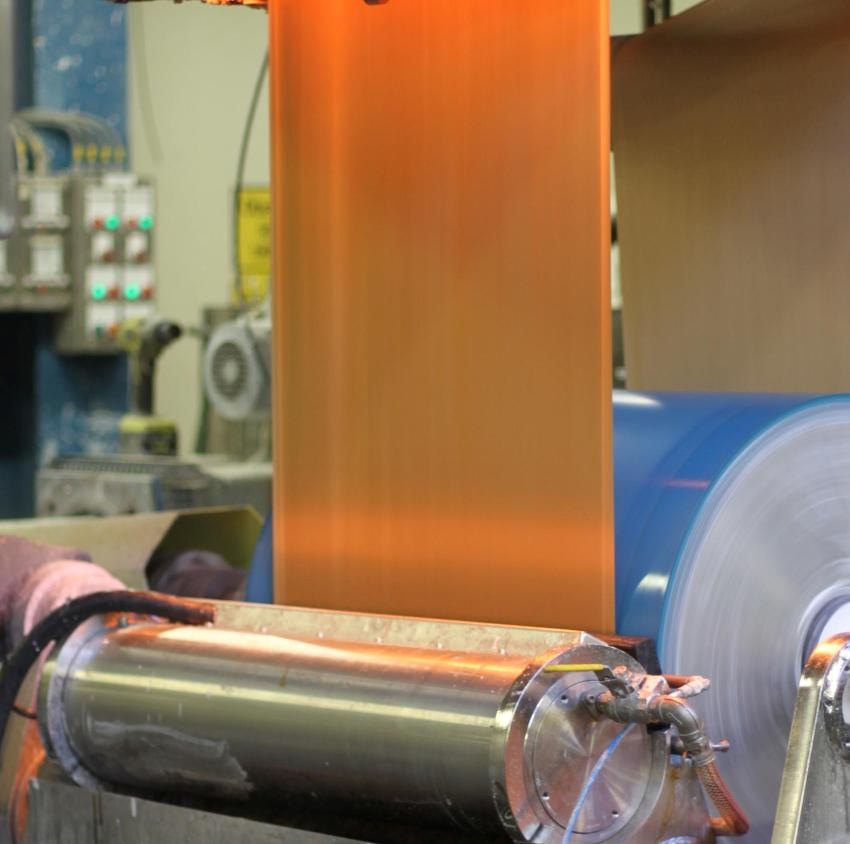

Credit: Karlstad University

Credit: Karlstad University

“Food packaging has to protect and extend the shelf life of food, and should also work during transport,” says Asif Javed, Doctor in Chemical Engineering at Karlstad University. “To meet these demands, a protective barrier is needed in paper-based packing such as those used for juice or dairy.”

A protective barrier against water and oxygen

Paper-based food packaging requires a coating to prevent oxygen or water from entering into the packaging and spoiling the foodstuff within. Typically this protective coating is made from petroleum-based plastic. For numerous years, scientists have been trying to discover a suitable bio-based material to substitute fossil-based raw materials. The study done at Karlstad University reveals that a blend of lignin from wood and starch from, for instance, maize or potatoes possibly can fulfill this job just as well as plastic.

“In my research, we used a mixture of starch and lignin to create a protective barrier that is up to scratch,” says Asif Javed.

If new materials are to be used, they have to be at least as good as or better than petroleum-based material – regarding extending the shelf life of food, as well as the cost and effectivity of manufacture and transport. I have also worked with biodegradable mixtures of starch and some petroleum-based macromolecules. Although such material is not 100% based on renewable resources, it has the important advantage of naturally degrading without leaving behind dangerous microplastics, should it end up in forests, lakes or oceans.

Asif Javed

Good prospects for future research

Nowadays various bio-based alternatives are already being employed in food packaging, but more research is necessary to substitute petroleum-based materials totally in the long term.

“I hope that we will be able to do more research in this area,” says Asif Javed. “In our region, there are good prospects for research on fibre-based processes and products in partnership with the industry. In my thesis project in the Vipp graduate school, I worked with Billerud Korsnäs.”

Staying in Värmland

In 2009, I came to Karlstad University from Pakistan to do my Master’s, without thinking that I’d stay on. Then I continued my doctoral studies in the Vipp graduate school, and now my wife, my daughter and I are settled here and we no longer plan on moving away from Karlstad.

Asif Javed

The study was conducted at the Vipp graduate school at Karlstad University and was sponsored by Billerud Korsnäs and the Knowledge Foundation. Vipp, the graduate school for value creation in fiber-based processes and products, is a partnership between Karlstad University and many different businesses, mainly in the forestry sector in Finland and Sweden.