Oct 17 2018

The future of electronics, in part, depends on the modification and advancement of silicon conductors.

Molecular electronics can contribute to this, and researchers in this field have been working on the development of scalable nanoscale electrodes that can be used to explore and manipulate molecular behavior to benefit electronic materials.

Credit: KTH

Credit: KTH

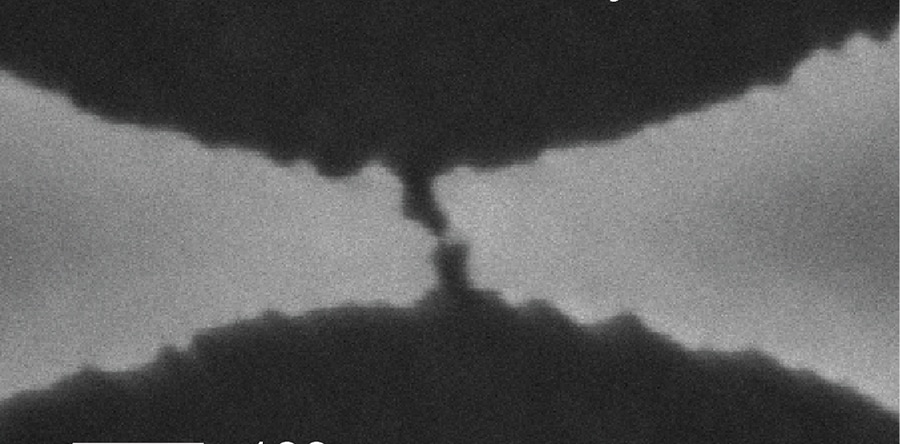

Now, a team from the Department of Micro and Nanosystems at KTH have successfully developed a method to develop millions of viable nanoscale molecular junctions. The findings were recently reported in Nature Communications.

The scientists claimed that with a 100 mm diameter wafer of thin materials, they could create as many as 20 million such electrodes within five hours, using a gold film on top of a brittle material that forms cracks.

The team partnered with the van der Zant Lab at TU Delft and managed to trap and examine an extensively-used reference molecule in the nanometer-wide space between the electrodes to confirm that the fabrication technique did not thwart the formation of molecular junctions.

Shyamprasad Natarajan Raja, one of the co-authors, says this “crack-defined break junction” technique offers a breakthrough to the gridlock of scalable production of structures that could someday enable electronic devices comprising of single molecules.

The key is to form gaps that enable a phenomenon referred to as tunneling, in which electrons prevail over the break in a circuit.

A break junction has a gap the size of a few atoms, which breaks the flow of electrons.

However, the gap is miniscule, and electrons with ample energy can still jump it.

Tunneling electrons withstand a small but measurable current that is very sensitive to the size of the gap – and to the presence of nano-objects within it.

Break junctions are the best means available to make single molecules part of a larger electronic circuit that can probe molecules.

However, tunneling break junctions are produced one gap at a time, which has been a major roadblock in developing any application involving tunneling junctions outside a research laboratory."

Shyamprasad Natarajan Raja, Co-author

The technique uses photolithography to pattern a stack of gold on titanium nitride (TiN).

This stack is placed on a silicon wafer, and the newly formed notched structures concentrate stress.

When the silicon directly below the stack is removed (a process known as release etching), minute cracks form at the pre-determined locations in the TiN which discharge the stress.

This, in turn, deforms the gold, stretching it into atomically thin wires running across these cracks, which upon breaking develops gaps as tiny as a molecule.

Raja says that the technique could be used for other conductive materials, offering remarkable chemical, electrical, and plasmonic properties for applications in molecular electronics and spintronics, biosensing, and nanoplasmonics.

The research received financial support from the Swedish Research Council (Grant No. 2016-04852) and the European Research Council (Grant No. 277879 and No. 812975).