Jan 14 2019

University of Michigan scientists have demonstrated that instead of constructing plastic filaments layer by layer, a new method to 3D printing lifts complex shapes from a vat of liquid at up to 100 times faster than conventional 3D printing processes.

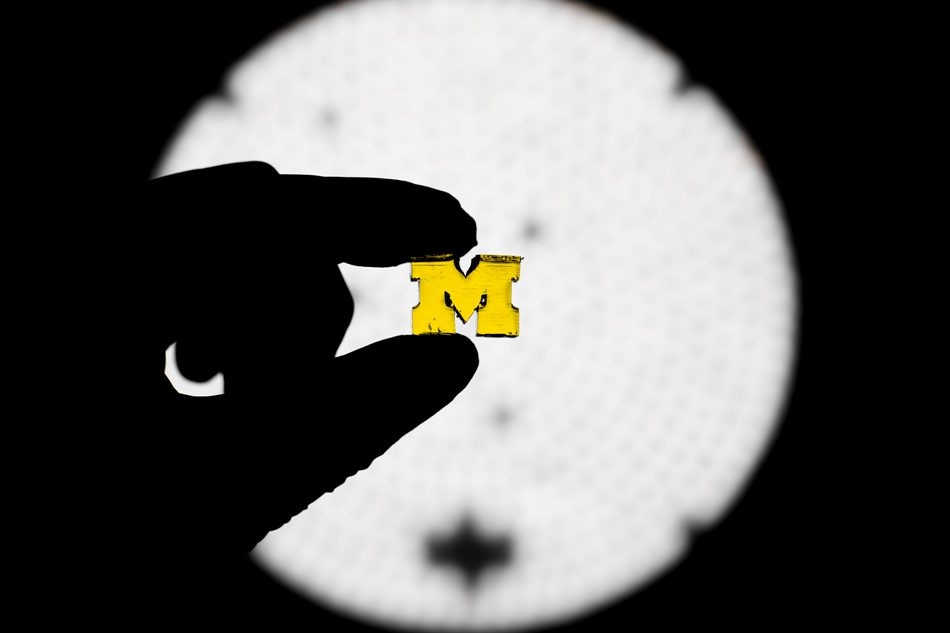

A new way to 3D print, developed at the University of Michigan, uses two lights to control the solidification of resin, enabling complex shapes to be pulled from a vat at 100 times the print speed of conventional 3D printers. (Image credit: Evan Dougherty)

A new way to 3D print, developed at the University of Michigan, uses two lights to control the solidification of resin, enabling complex shapes to be pulled from a vat at 100 times the print speed of conventional 3D printers. (Image credit: Evan Dougherty)

3D printing could alter the game for comparatively small manufacturing operations, producing fewer than 10,000 identical items, as it would mean that the objects could be created without the need for a mold costing over $10,000. But the most accustomed form of 3D printing, which is quite like constructing 3D objects with a series of 1D lines, has not been able to match up to the standard production timescales of a week or two.

“Using conventional approaches, that’s not really attainable unless you have hundreds of machines,” said Timothy Scott, U-M associate professor of chemical engineering who co-led the development of the new 3D printing method with Mark Burns, the T.C. Chang Professor of Engineering at U-M.

Their technique solidifies the liquid resin using two lights to regulate where the resin hardens—and where it remains fluid. This allows the team to harden the resin in more sophisticated patterns. They can make a 3D bas-relief in a single shot instead of in a series of 1D lines or 2D cross-sections. Their printing demonstrations include a toy boat, a lattice, and a block M.

It’s one of the first true 3D printers ever made.

Mark Burns, T.C. Chang Professor of Engineering, U-M

But the real 3D approach is no simple stunt—it was necessary to surpass the limitations of earlier vat-printing efforts. Specifically, the resin tends to solidify on the window that the light shines through, halting the print job just as it commences.

By developing a comparatively large region where no solidification takes place, thicker resins—possibly with strengthening powder additives—can be used to create more long-lasting objects. The technique also bests the structural integrity of filament 3D printing, as those objects have weak points at the interfaces between layers.

“You can get much tougher, much more wear-resistant materials,” Scott said.

A previous solution to the solidification-on-window problem was a window that allows oxygen through. The oxygen enters into the resin and stops the solidification near the window, leaving a film of fluid that will permit the newly printed surface to be pulled away.

But since this gap is just about as thick as a piece of transparent tape, the resin must be extremely runny to flow quickly enough into the minute gap between the newly solidified object and the window as the part is pulled up. This has limited vat printing to small, tailored products that will be treated comparatively gently, such as shoe insoles and dental devices.

By substituting the oxygen with a second light to stop solidification, the Michigan team can create a much larger gap between the object and the window—millimeters thick—permitting resin to flow in thousands of times faster.

The key to triumph is the chemistry of the resin. In conventional systems, there is just one reaction. A photoactivator makes the resin hard wherever light shines. In the Michigan system, there is also a photoinhibitor, which reacts to a different wavelength of light.

Instead of just manipulating solidification in a 2D plane, as existing vat-printing methods do, the Michigan team can pattern the two kinds of light to harden the resin at basically any 3D place near the illumination window.

U-M has filed three patent applications to safeguard the many inventive aspects of the method, and Scott is preparing to float a startup company.

A paper illustrating this study will be published in Science Advances, titled, “Rapid, continuous additive manufacturing by volumetric polymerization inhibition patterning.”

3D printing 100 times faster with resin