Feb 27 2019

A team of researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences, has come up with an innovative technique for performing lignocellulose conversion in a cost-effective way.

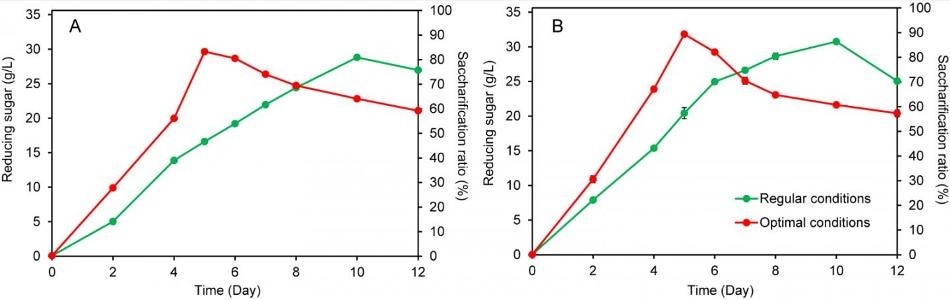

Saccharification of pretreated wheat straw under optimal or regular conditions without modification in both 100-mL anaerobic bottles (A) and a 10-L anaerobic fermenter (B). (Image credit: Liu Yajun)

Saccharification of pretreated wheat straw under optimal or regular conditions without modification in both 100-mL anaerobic bottles (A) and a 10-L anaerobic fermenter (B). (Image credit: Liu Yajun)

The new process, called the consolidated bio-saccharification (CBS), merges hydrolysis and cellulase production during the separation of fermentation from the integrated process using fermentable sugar as the target product to combine several downstream fermentation processes.

Lignocellulose solubilization has limited the commercial conversion of biomass to high-value biochemicals and biofuels. Previous studies reported three approaches for lignocellulose bioconversion: simultaneous saccharification and fermentation (SSF), separate enzymatic hydrolysis and fermentation (SHF), and consolidated bioprocessing (CBP).

In the case of SSF and SHF, in general, cellulases are aerobically synthesized by fungi in a separate reactor. The cost of the enzyme has to be taken into account as a key problem. On the contrary, CBP combines cellulose hydrolysis, fermentation, and enzyme production in a single step to lower the cost of cellulase and investment. However, it requires basic products and has comparatively low saccharification efficiency.

Earlier, the researchers from the QIBEBT had synthesized a CBS biocatalyst by genetically engineering Clostridium thermocellum. They took years to attain a high saccharification level. Eventually, a second-generation CBS biocatalyst was developed. To improve the saccharification efficiency and lower the cost, the essential process factors, such as inoculum, substrate load, and the medium, were optimized.

The CBS process was cut short using the newly developed biocatalyst and optimal conditions, as well as using 50% pretreated wheat straw as the substrate. In this case, the saccharification level was 89.3%, and the yield of the sugar was 0.795 g/g.

CBS is expected to be widely used in producing various lignocellulose-derived chemicals, functional foods and pharmaceuticals. The construction of a pilot-scale CBS demonstration is underway.

Prof. Qiu Cui, Study Corresponding Author, Chinese Academy of Sciences.

Published in Biotechnology for Biofuels on February 18th, 2019, the study was supported by the Transformational Technologies for Clean Energy and Demonstration Program of the Strategic Priority Research Program of the Chinese Academy of Sciences, the National Natural Science Foundation of China, the Key Technology Research and Development Program of Shandong, and the Major Program of the Shandong Provincial Natural Science Foundation.