May 7 2019

Scientists from Tokyo University of Agriculture and Technology (TUAT), ORC Manufacturing Co. Ltd. and Techno Research., Ltd accomplished superior quality crystallization of amorphous silicon film by creating rapid heating technology using the microwave induced wireless heating lamp. The wireless lamp is outstanding in energy saving, maintainability, and durability, and it can be projected to be developed into a new heating device that is unparalleled. Details of this research were published online on February 7th, 2019 in IEEE Access of the Institute of Electrical and Electronics Engineers (IEEE) in an article titled “Carbon Heating Tube Used for Rapid Heating System.”

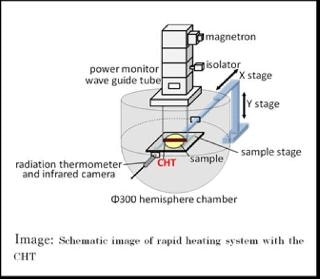

Schematic image of rapid heating system with the CHT. (Image credit: Tokyo University of Agriculture and Technology)

Schematic image of rapid heating system with the CHT. (Image credit: Tokyo University of Agriculture and Technology)

Present

Keeping in mind the environment, power saving of a heating equipment is required. Furthermore, there is a great demand for a long-life heating lamp that does not cause disconnection due to heat stress and a lamp unit that does not need to be frequently replaced and is easy to set up. Power cost reduction, downtime reduction, and maintenance cost reduction, are estimated to have a ripple effect in all product manufacturing areas that necessitate heating.

Present structure

This research was undertaken by the study team of Professor Toshiyuki Sameishima, Associate Professor Takuji Arima, Assistant Professor Harumi Hasumi and others at Tokyo University of Agriculture and Technology Graduate School of Engineering, Oak Manufacturing Co., Ltd., and Techno Research Inc. This work was partly aided by Japan Science and Technology Agency ASTEP (No. AS3015022S).

Research result

The study team has built an electrodeless lamp, carbon heating tube (CHT), wherein carbon particles filled in a quartz tube with argon gas. The CHT was irradiated using 200 W of microwave causing the carbon particles to absorb the microwave and get heated to 1279 °C.

CHT does not need electrical wiring which is exceptional in durability. Furthermore, it is a type of energy-saving heating lamp which does not create heat leaks via the wiring. Also, there is no need for rare metals so it is possible to make it economically. This time a prototype of rapid heating equipment was created using CHT. The microwave added into the chamber via the waveguide tube is successfully absorbed by the CHT. The CHT temperature was measured using a radiation thermometer and the microwave power was regulated to tweak the heating temperature. Using this heating system to crystallize, an amorphous silicon thin film sample developed on a 4-inch quartz glass substrate. The analysis outcome of the spectral reflectance spectrum and the Raman scattering spectrum revealed a superior quality crystallized film and a high crystallization ratio of 0.92, which comparable to the laser crystallized film was developed over the total surface of the sample. The current results show the likelihood of numerous applications of heating system using CHT.