Jun 10 2019

An extremely efficient catalyst for extracting electrical energy from ethanol has been created researchers at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory and the University of Arkansas. The new catalyst is an easy-to-store liquid fuel that can be produced from renewable resources.

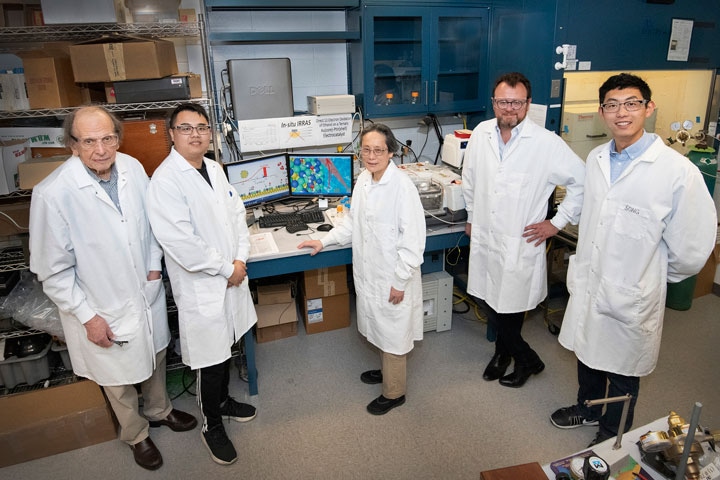

Brookhaven Lab members of the research team that developed and characterized a new core-shell catalyst for complete electro-oxidation of ethanol (l to r): Radoslav Adzic, Zhixiu Liang, Jia Wang, Eli Stavitski, and Liang Song. (Image credit: Brookhaven National Laboratory)

Brookhaven Lab members of the research team that developed and characterized a new core-shell catalyst for complete electro-oxidation of ethanol (l to r): Radoslav Adzic, Zhixiu Liang, Jia Wang, Eli Stavitski, and Liang Song. (Image credit: Brookhaven National Laboratory)

The catalyst has been illustrated in the Journal of the American Chemical Society, directs the electro-oxidation of ethanol down a suitable chemical pathway that discharges the liquid fuel’s complete potential of stored energy.

“This catalyst is a game changer that will enable the use of ethanol fuel cells as a promising high-energy-density source of ‘off-the-grid’ electrical power,” said Jia Wang, the Brookhaven Lab chemist who led the research. One very favorable application: liquid fuel-cell-powered drones.

“Ethanol fuel cells are lightweight compared to batteries. They would provide sufficient power for operating drones using a liquid fuel that’s easy to refill between flights—even in remote locations,” Wang noted.

Most of the potential power in ethanol is sealed in the carbon-carbon bonds that form the spine of the molecule. The catalyst engineered by Wang’s team exposes that breaking those bonds at the appropriate time is paramount in releasing that stored energy.

Electro-oxidation of ethanol can produce 12 electrons per molecule. But the reaction can progress by following many different pathways.

Jia Wang, Study Lead and Chemist, Brookhaven Lab

The majority of these pathways cause partial oxidation: The catalysts leave carbon-carbon bonds untouched, discharging fewer electrons. They also remove hydrogen atoms early in the process, exposing carbon atoms to the carbon monoxide formation, which “poisons” the catalysts’ capability to operate over time.

“The 12-electron full oxidation of ethanol requires breaking the carbon-carbon bond at the beginning of the process, while hydrogen atoms are still attached, because the hydrogen protects the carbon and prevents the formation of carbon monoxide,” Wang said. Then, many steps of dehydrogenation and oxidation are necessary to finish the process.

The new catalyst—which integrates reactive elements in an exclusive core-shell structure that Brookhaven researchers have been examining for a variety of catalytic reactions—accelerates all of these steps.

To create the catalyst, Jingyi Chen of the University of Arkansas, who was a visiting expert at Brookhaven during part of this project, formulated a synthesis technique to co-deposit iridium and platinum on gold nanoparticles. The iridium and platinum form “monoatomic islands” across the surface of the gold nanoparticles. That setup, Chen explained, is the key that is responsible for the catalyst’s exceptional performance.

“The gold nanoparticle cores induce tensile strain in the platinum-iridium monoatomic islands, which increases those elements’ ability to cleave the carbon-carbon bonds, and then strip away its hydrogen atoms,” she said.

Zhixiu Liang, a Stony Brook University graduate student and the paper’s first author, conducted studies in Wang’s lab to comprehend how the catalyst realizes its record-high energy conversion efficiency. He used “in situ infrared reflection-absorption spectroscopy” to recognize the reaction intermediates and products, comparing those created by the new catalyst with reactions using a gold-core/platinum-shell catalyst as well as a platinum-iridium alloy catalyst.

By measuring the spectra produced when the infrared light is absorbed at different steps in the reaction, this method allows us to track, at each step, what species have been formed and how much of each product. The spectra revealed that the new catalyst steers ethanol toward the 12-electron full oxidation pathway, releasing the fuel’s full potential of stored energy.

Zhixiu Liang, Paper’s First Author and Graduate Student, Stony Brook University

The following step, Wang plans, is to design devices that add the new catalyst.

The mechanistic details publicized by this study may also help direct the balanced design of future multicomponent catalysts for other applications.

Besides the details given here, the researchers used the Inner Shell Spectroscopy (ISS) beamline at the National Synchrotron Light Source II (NSLS-II)—a DOE Office of Science User Facility—to define the relative quantities of each element in the catalyst samples. The paper’s other co-authors are Liang Song and Radoslav R. Adzic of Brookhaven Lab’s Chemistry Division, Shiqing Deng and Yimei Zhu of the Lab’s Condensed Matter Physics and Materials Science Division, and Eli Stavitski of NSLS-II.

The U.S. Department of Energy’s Office of Science and the National Science Foundation funded this work.