Jun 26 2019

Condensation could fog up glasses or ruin a wood coffee table when it enters into a warm building on a winter day, but it is not completely a problem. The condensation and evaporation cycle has significant applications.

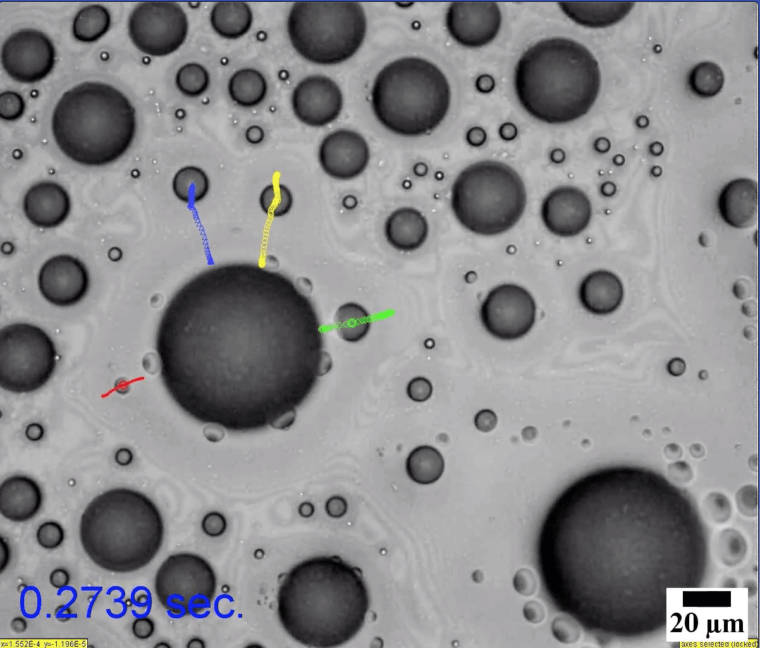

New research from the McKelvey School of Engineering reveals the way in which small water droplets move in the area of influence of a larger droplet on a liquid infused surface. The small droplets move toward the larger one, clearing space for new droplets to form. (Image: Weisensee lab)

New research from the McKelvey School of Engineering reveals the way in which small water droplets move in the area of influence of a larger droplet on a liquid infused surface. The small droplets move toward the larger one, clearing space for new droplets to form. (Image: Weisensee lab)

Water can be collected from “thin air,” or separated from salt in desalination plants using condensation. Owing to the fact condensing droplets take heat with them when they evaporate, it is also part of the cooling process in the industrial and high-powered computing fields. Yet when scientists studied the newest method of condensation, they noticed something odd: When a special type of surface was covered in a thin layer of oil, condensed water droplets appeared to be haphazardly flying across the surface at high velocities, integrating with larger droplets, in patterns not triggered by gravity.

“They’re so far apart, in terms of their own, relative dimensions” — the droplets have a diameter smaller than 50 µm — “and yet they’re getting pulled, and moving at really high velocities,” said Patricia Weisensee, assistant professor of mechanical engineering & materials science in the McKelvey School of Engineering at Washington University in St. Louis.

“They’re all moving toward the bigger droplets at speeds of up to 1 mm per second.”

Weisensee and Jianxing Sun, a PhD candidate in her lab, have established that the apparently-erratic movement is the result of unstable capillary forces acting on the droplets. They also learned that the droplets’ speed is a function of the size of the droplets and the oil’s viscosity, which means droplet speed is something that can be regulated.

Their results were reported online in Soft Matter.

“Why are they moving?”

In the most typical kind of condensation in industry, water vapor condenses to create a thick layer of liquid on a surface. This technique is called filmwise condensation. But another technique has been proven to be more effective at boosting condensation and the transfer of heat that is a part of it: dropwise condensation.

It has been applied on traditionally hydrophobic surfaces — those that repel water like the Teflon coating on a non-stick pan. However, these traditional non-wetting surfaces deteriorate quickly when open to hot vapor. Instead, some years ago, scientists learned that infusing a rugged or porous hydrophobic surface with a lubricant, such as oil results in faster condensation.

Significantly, these lubricant-infused surfaces (LIS) led to the development of extremely mobile and smaller water droplets, which are accountable for most of the heat transfer with regards to condensation and evaporation.

In the process, however, the water droplet movement on the surface looked erratic — and rapid. “They move at a really high velocity for their size,” — about 100 microns — “just by sitting there,” Weisensee said.

“The question is, ‘Why are they moving?’ ”

Using high-speed microscopy and interferometry to observe how the process takes place, Weisensee and her team were able to distinguish what was taking place and the relationships between oil viscosity, droplet size, and speed.

They formed water vapor and observed as small droplets developed on the surface. “The first process is that small droplets coalesce and form bigger droplets,” Weisensee said. Capillary forces make the oil to rise up and over the droplets, forming a meniscus — not the knee muscle, but actually a curved layer of oil surrounding the droplet.

The oil is incessantly moving around, attempting to strike a balance as it encompasses different-sized droplets in various places on the surface — if a large droplet develops here, the meniscus stretches over it, making the oil layer to contract elsewhere. Any smaller droplets in the area of contraction are quickly pulled to the larger droplets, resulting in oil-rich and oil-poor areas.

During the process, larger droplets are fundamentally clearing the space, which in turn makes space for the development of more small droplets.

As most of the heat transfer (about 85%) happens via these small droplets, using LIS for dropwise condensation will be a more efficient way to scatter heat and obtain water from vapor. Furthermore, since the droplets are tiny, less than 100 µm in diameter, condensation can happen in a smaller area.

There is another advantage, too. During “traditional” condensation, gravity is the force that clears water from the surface, making space for new droplets to develop. The surface is positioned vertically, and the water just runs off. Since capillary forces are taking control in dropwise condensation on liquid-infused surfaces, surface orientation is of no effect.

“It could potentially be used on personal devices,” where orientation is continuously changing, she said, “or in space.” And since the whole process is more efficient compared to traditional condensation, Weisensee said, “This might be a nice way of clearing up space without having to rely on gravity.”

In the months ahead, Weisensee’s team will measure heat transfer to establish if the smaller droplets during dropwise condensation on LIS are, actually, more efficient. They also aim to examine various surfaces so as to maximize droplet movement.