Jul 18 2019

One of the main objectives of researchers is to develop dynamic synthetic materials that are similar to those found in nature, have reversibly changing characteristics, and can possibly be used in recycling, manufacturing, and many other different applications.

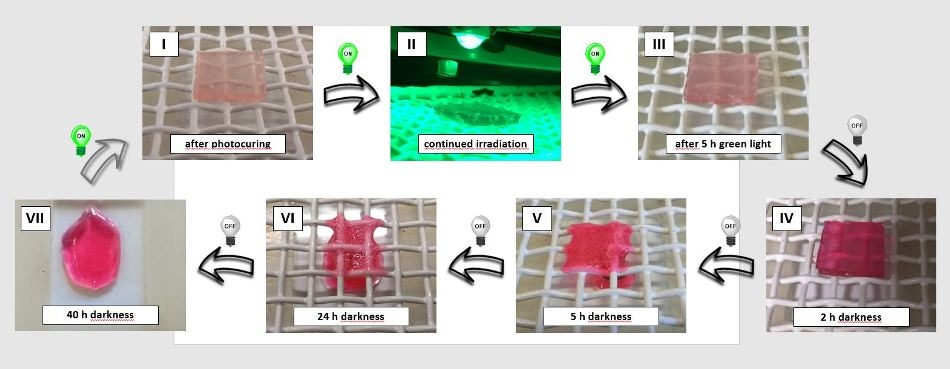

Naphthalene-TAD material light-stabilized dynamic behavior. (Image credit QUT/UGent/KIT)

Naphthalene-TAD material light-stabilized dynamic behavior. (Image credit QUT/UGent/KIT)

In the first-ever study, researchers from Queensland University of Technology (QUT), Germany’s Karlsruhe Institute of Technology (KIT), and Belgium’s Ghent University (UGent) have developed a new, dynamic, reprogrammable material by utilizing green LED light. Incredibly, they were also able to change the polymer structure of the material by using darkness as the switches and using just a couple of low-cost chemical compounds. Naphthalene—a popular ingredient in moth repellents—is one of these compounds.

The latest dynamic material can perhaps be utilized as a 3D printing ink for printing easy-to-remove and temporary support scaffolds. This application can help in resolving one of the present limitations faced in the 3D process when printing free-hanging structures.

The study is part of an ongoing international association between QUT macromolecular chemist and Australian Research Council Laureate Fellow Professor Christopher Barner-Kowollik, Dr Hannes Houck, who recently finished his PhD across KIT, UGent, and QUT, KIT’s Dr Eva Blasco, and UGent Professor Filip Du Prez.

The results of the study have been reported in the Journal of the American Chemical Society (JACS).

Key points:

- The novel material was created with the coupling molecules triazolinediones (TADs) and naphthalenes

- The material remained strong and stable as long as a green LED light is shone on the material

- Switching off the light and keeping the material in total darkness caused the chemical bonds of the network structure to break up and rendered the material to become soft and liquefied

- The hard-to-soft process can be repeated by flicking the switch, and the material’s mechanical properties can be modulated by dimming the light

- Follow on studies are examining other chemical combinations that can deliver the same outcome

According to Professor Barner-Kowollik from QUT’s Science and Engineering Faculty, the uniqueness of this discovery is that light is utilized as the trigger to stabilize and not destroy chemical bonds. This made the investigators to come up with a new term called light-stabilized dynamic materials (LSDMs).

We are hoping to introduce LSDMs as a whole new class of materials. We debated whether to patent the new material, but decided not to wait and to publish the findings to advance knowledge and understanding of the processes involved.

Dr Hannes Houck, Queensland University of Technology

According to the researchers, what they have accomplished is the opposite of what is frequently done in chemistry and “many people didn’t think it could be done.”

“Typically, you use different wavelengths of light or additional heat or harsh chemicals to break up the polymer molecule chains that form a network structure,” the researchers stated.

They continued, “However, in this case, we used green LED light to stabilise the network. The trigger to break up the network, make it collapse and flow away is actually the mildest one of all: darkness. Switch the light back on and the material re-hardens and retains its strength and stability.

“This is what you call an out-of-equilibrium chemical system. The constant energy of the green light keeps the chemical system in this bonded form, pushing it out of its equilibrium. Take away the light, and the system goes back to its relaxed, lowest energy state.”

Professor Barner-Kowollik informed that 3D printing technology companies keen on applying the research have already contacted the researchers.

In the automotive and aerospace sectors, 3D printing is used for making detailed prototypes and intricate parts. Conversely, it is difficult or off limits to 3D print complex designs with bridges or overhangs, because in the 3D process, layer upon layer has to be printed and there is no direct support for layers in structures that are sharply angled.

What you need to 3D print something like a bridge is a support scaffold, a second ink that provides that scaffold during printing of the design, but which you can later remove when it is no longer needed.

Christopher Barner-Kowollik, Macromolecular Chemist and Australian Research Council Laureate Fellow, QUT

He continued, “With a light-stabilised dynamic ink used as a scaffold you could 3D print under light, then switch the light off to let the scaffold ink flow away.”

According to Professor Barner-Kowollik and Professor Du Prez, LSDMs can be potentially used as a cell biology study tool, with biologists utilizing it as a cell surface support that can be modified by light modulation without causing damage to the cells.

Light-stabilised dynamic material

An international team of researchers at QUT, UGent, and KIT have pioneered a novel, dynamic and reprogrammable material which is stable under visible green light, then becomes fluid over time in darkness. (Video credit: QUT/UGent/KIT)