By Toby CharnockOct 15 2019

By Toby CharnockOct 15 2019A recent study performed by North Carolina State (NC State) University revealed that exceptional materials with distinct properties—similar to those of gecko feet—can be produced by exploiting liquid-driven chaos to create soft polymer microparticles with hierarchical branching on the micro- and nanoscale.

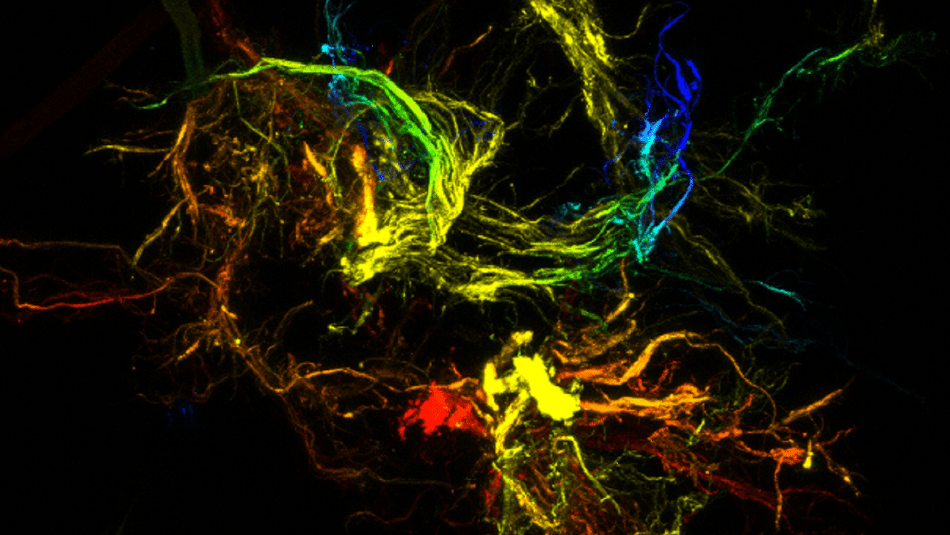

Branched, sticky particles are the result of harnessing liquid chaos. (Image credit: Orlin Velev, NC State University).

Branched, sticky particles are the result of harnessing liquid chaos. (Image credit: Orlin Velev, NC State University).

Gecko feet are capable of sticking to virtually any surface.

Described in the journal Nature Materials, the findings hold the possibility for developments in nonwovens, gels, foods, coatings, and pastes, among other formulations.

The soft dendritic particle materials with distinctive adhesive and structure-building characteristics can be produced from a wide range of polymers precipitated from solutions under exceptional conditions, stated Orlin Velev, the S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State and the paper’s corresponding author.

We use ‘liquid’ nanomanufacturing to convert most polymers into branched particles after dissolving the polymer and mixing the solution rapidly with another liquid. This rapid mixing in turbulent flow creates branched particles organized in a hierarchical way.

Orlin Velev, Study Corresponding Author and Professor, Department of Chemical and Biomolecular Engineering, North Carolina State University

Velev added that the thinnest branches enclosing these particles form a corona of nanofibers, which spread their stickiness by molecular forces of attraction called van der Waals forces.

The novel material has an exclusive structure and is also fabricated in a unique manner.

The use of turbulent flow is ordinarily not known as a way to fabricate organized structures. Here, we are using this inherently chaotic process to create hierarchical structures.

Orlin Velev, Study Corresponding Author and Professor, Department of Chemical and Biomolecular Engineering, North Carolina State University

The liquid process used for producing these materials is effective with many varieties of polymers and is mostly efficient and economical. Velev explained that the fabrication process can be effortlessly expanded to create large volumes of the soft nanomaterial, which usually poses a challenge when it comes to producing materials at the micro-and nanoscale.

The aim of upcoming research in Velev’s laboratory will be to obtain the fundamentals underlying this incredible discovery. Research will also inspect the various kinds of biopolymer and polymer materials that can be developed using the process, including sheets and coatings that repel or attract water, for instance, or 3D printing pastes and cell scaffolds. A patent has been filed by NC State for the new soft dendritic materials and the process for creating them.

This work is an illustration of how fundamental and applied science can work synergistically. We started with fundamental scientific findings and while investigating them we found many new applications such as super-adhesives and coatings, which in turn brought new fundamental questions regarding their properties.

Simeon Stoyanov, Study Co-Author and Research Collaborator, North Carolina State University

Former PhD student Sangchul Roh is a co-inventor of the nanofabrication process and the paper’s first author. The paper was also co-authored by graduate students Austin Williams and Rachel Bang, who are pursuing the study of the formation and applications of the new material.

The study received funding from the National Science Foundation under grants CMMI-1825476, CBET-1604116 and from NC State’s Chancellor’s Innovation Fund.