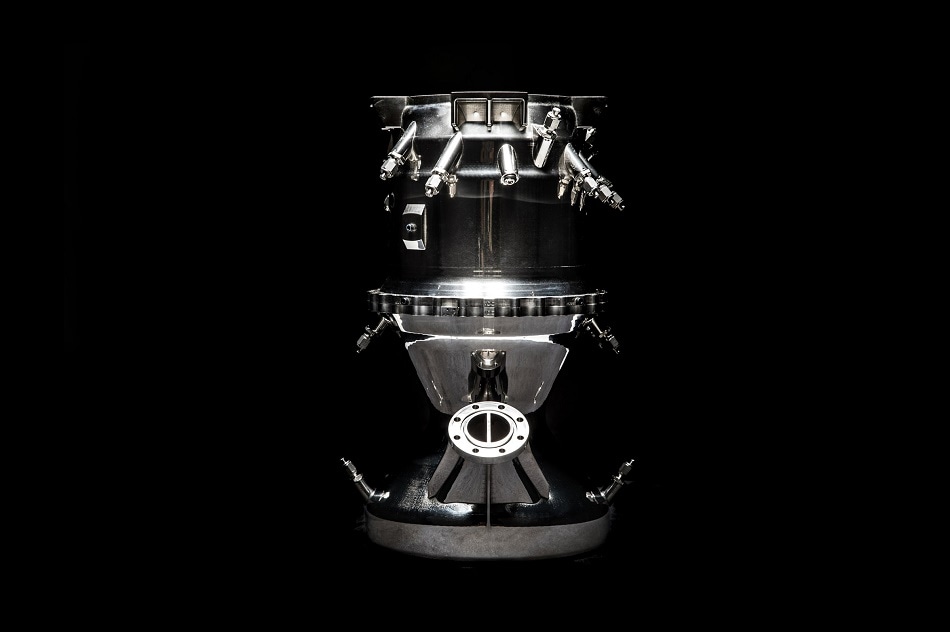

Image Credit: Relativity

The LA-based startup, Relativity Space, are combining Artificial Intelligence (AI) with four of the world’s largest metal 3D printers, the result is rocket parts printed day and night under the instructions of AI. Theoretically, this method of working could see rockets being created on the surface of mars, without the need for physical human intervention.

Doing For Rockets What Henry Ford Did For The Automobile

The chief executive and co-founder of Relativity Space, Tim Ellis, created the company with the ambition to do for the rocket what Henry Ford did for the automobile. He wants to combine 3D printing with AI so that rockets could be built anywhere.

Specifically, Ellis aims to one day be printing rockets on Mars. However this may be some years in the future, the startup has only recently completed printing the upper stage of their rocket, which will shortly be put to its first tests. Relativity Space recently received $140 million in Series C funding to help get them to their aim of launching the world’s first 3D printed rocket.

Printing Rockets on Mars

In order to reach their goal of creating a method for allowing rockets to be printed on Mars, the team at Relativity Space are using four of the world’s largest metal 3D printers to create 95% of the components needed for their first rocket, Terran-1. The latest of these printers being known as Stargate, which is 30 feet tall, with two giant robotic arms. The other 5% of the components that will not be printed are the electronics, cables and a minimal number of moving parts and rubber gaskets.

The team is not just printing a regular rocket. They have had to redesign it to allow it to be possible to be printed. For example, Terran-1 will have 100 times fewer parts than a conventional rocket of a similar size. They have optimized the design for the purpose of 3D printing, making it possible to turn raw materials into a fully functional rocket, ready on the launch pad in 60 days. However, the company’s first rocket isn’t expected to launch until 2021.

More than utilizing huge industrial 3D printers, the impressive achievement of Relativity Space is in their development of machine learning algorithms with the capabilities of recognizing mistakes in the printing process, and allowing the machines to correct their own work, meaning that minimal human interference is required. In addition to this, the more the system works, the better it gets at recognizing its mistakes, making it function better and better over time.

The first step will be extensive testing to ensure that this new technology works as it should, certifying the 3D printed rocket as safe for space flight. Following testing, Relativity Space will begin to explore the nature of the future for their innovation. They will answer questions regarding the need for self printing rockets, and how they can be used for further space exploration and what the significance of being able to remotely 3D print on other planets would be.

Ellis believes the impact of the work his company is doing will have influences outside that of advancing rocket production. Creating a method to create complex working machinery on other planets will expand possibilities for human experience in space that will occur within our lifetimes.

Launch of The First 3D Printed Rocket

Relativity Space already has a long-term launchpad lease at the Kennedy Space Center, in Florida. Once it has passed extensive testing, the rocket will be launched from this space where SpaceX, Blue Origin, and the United Launch Alliance also hold leases. Expected to happen as early as 2021, the maiden voyage will mark a significant step forward in space exploration, as well as being a key part of the journey to enabling 3D printing on other planets.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.