Nov 8 2019

Scientists at KAUST have combined four polymers, by manipulating four different chemical reactions in a single flask, to form a single multicrystalline substance. Materials that flawlessly combine several polymers potentially blend the finest features of each material.

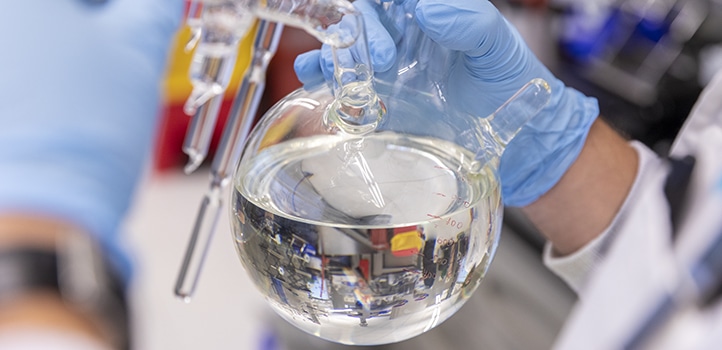

Hadjichristidis and his team found that using catalyst switching saves time and avoids the risk of any contamination of the polymer. Image Credit: © 2019 KAUST

Hadjichristidis and his team found that using catalyst switching saves time and avoids the risk of any contamination of the polymer. Image Credit: © 2019 KAUST

The adaptable new method for developing these “multicrystalline multiblock polymers,” formulated by Nikos Hadjichristidis from the KAUST Catalysis Center and his colleagues, in partnership with Yves Gnanou, could pave the way to a completely new class of advanced polymer materials.

Polymers are long-chain molecules created by linking together small molecule “monomeric units,” like a string of identical beads on a necklace. Scientists have recently created ways to form “double-crystalline” copolymers in which one part of the chain is developed from one type of monomer and the other part is developed from another.

“Double-crystalline block copolymers have myriad applications, such as for energy storage, tissue engineering and drug delivery,” stated Viko Ladelta, a member of Hadjichristidis’ team.

Incorporating an even greater number of distinct polymer sections could potentially yield materials with even more sophisticated properties.

But the synthetic procedures are very demanding. It was difficult to perform even the synthesis of double-crystalline block copolymers, due to the incompatibility of the monomers and catalysts.

Viko Ladelta, KAUST Catalysis Center

Creating materials that include four distinct monomers in four chemically diverse blocks—tetra-crystalline tetrablock quarterpolymers—results in even greater incompatibility.

Hadjichristidis and his colleagues have devised a trick, known as catalyst switching, to help resolve the incompatibility issue. A majority of the organic catalysts used for a polymer-forming reaction, known as ring-opening polymerization, are either acids or bases.

Multiblock polymers can be synthesized in a single reaction flask by the addition of one type of monomer to the polymer chain under regular conditions, and subsequently adjusting the pH and adding a second catalyst to the next monomer.

This strategy saves time and also avoids the risk of any contamination of the polymer.

Viko Ladelta, KAUST Catalysis Center

Hadjichristidis’ team has earlier applied catalyst switching between organic catalysts to form double-crystalline and triple-crystalline polymers. At present, for the first time, the team has demonstrated it is possible to regulate the pH, then change from an organic to a metal catalyst, to produce a tetracrystalline tetrablock quarterpolymer.

Our plan is to expand the scope of the catalyst switch strategy to other types of polymerization. We will synthesize more complex multicrystalline polymers and collaborate with polymer physicists to understand the physical properties to guide us toward real-world applications.

Viko Ladelta, KAUST Catalysis Center

Catalyst switching means four become one

The new approach for creating these multicrystalline multiblock polymers could lead to a whole new family of advanced polymer materials. Video Credit: © 2019 KAUST