Feb 6 2020

CIGSe (copper, indium, gallium, and selenium)-based, thin-film solar cells can be produced cost-effectively, and now these solar cells can also achieve excellent efficiencies of more than 20%.

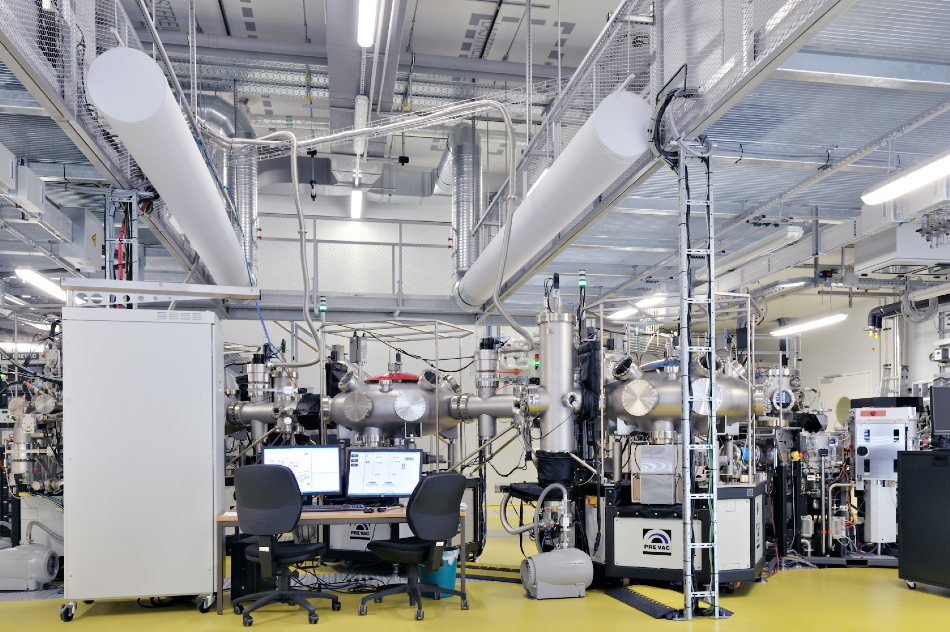

Research on the EU project Sharc25 also took place in the EMIL laboratory, where thin films and materials can be analyzed with X-rays from BESSY II. Image Credit: © Ingo Kniest/HZB.

Research on the EU project Sharc25 also took place in the EMIL laboratory, where thin films and materials can be analyzed with X-rays from BESSY II. Image Credit: © Ingo Kniest/HZB.

Such remarkable levels of performance were realized by post-processing with alkali elements, and the processes involved are appropriate for commercial-scale production.

A better understanding of the useful effect of these treatments of alkali elements from the European (EU) Sharc25 research project has currently been reported in an article published in the Advanced Energy Materials journal.

When compared to traditional wafer-based Si PV modules, the production of thin-film solar modules needs relatively less energy, which means their energy payback time is also relatively shorter.

Chalcopyrite-structured compounds of CIGSe are a major class of materials developed for thin-film solar cells. The reason is CIGSe can absorb incident light relatively better when compared to silicon and, therefore, an extremely thin layer of CIGSe, grown on a substrate through co-evaporation, is enough to efficiently change light into electrical energy.

Efficiency up to 22.6%

The EU Sharc25 research project tackled the challenge of improving the conversion efficiency factor of CIGSe thin-film technology from various angles, by integrating experimental characterization, theoretical modeling, and sharing of technological know-how between many top research groups across Europe.

During the EU Sharc25 project, the efficiency of CIGSe-based solar cells fabricated within the consortium increased from 21.7% to 22.6%.

One of the goals of the research project was to figure out the positive impacts of post-processing with cesium, rubidium, and potassium, which are all alkali elements. This post-processing alters the electronic and chemical surface characteristics of the CIGSe absorber. Moreover, the alkali atoms move from the surface into the grain boundaries that exist between the CIGSe grains, which, in turn, enhance the thin film’s electronic properties.

Among other effects, the reintegration of charge carriers in the bulk CIGSe is decreased. This advantageous effect is seen for CIGSe layers that were prepared on different substrates and at different temperatures.

Know-How for European Industries

The EU Sharc25 research project involved 11 research institutions from 8 nations, including an HZB team led by Professor Marcus Bär. A crucial objective of the EU Sharc25 research project was to establish Europe’s ground-breaking role in the domain of thin-film PV.

It is certainly a competitive advantage to be able to address questions related to applied materials research and to the development of industry-oriented devices using advanced research tools. To do so efficiently, we learn in such large EU projects. This represents a significant advantage and preserves the crucial edge in knowledge and know-how.

Marcus Bär, Professor, HZB

Partners include EMPA (CH), the Universities of Luxembourg (LU), Rouen (F), Parma (I), and Aalto (FIN), IMEC (B), HZB (D), INL (P), Flisom AG (CH), and Manz CIGS Technology GmbH (D). The project was coordinated by the Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW).

“Heavy alkali treatment of Cu(In,Ga)Se2 solar cells: Surface versus bulk effects” is the title of the study published in the Advanced Energy Materials journal.