Oct 7 2020

A KAUST research team, exploring thin films capable of turning thermal energy into electricity, state that a polymer formerly used to safeguard solar cells could be used in new applications in the field of consumer electronics.

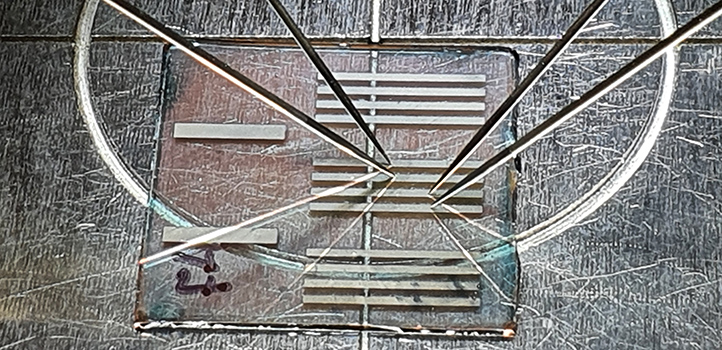

Diego Rosas-Villalva explained that the team was surprised that such an extremely thin polymer was so effective in improving the lifetime of the device. (Image Credit: © 2020 KAUST)

Diego Rosas-Villalva explained that the team was surprised that such an extremely thin polymer was so effective in improving the lifetime of the device. (Image Credit: © 2020 KAUST)

When two sides of a semiconductor have varying temperatures, electron movement from hot to cool areas can produce a current. This occurrence, called the thermoelectric effect, usually requires semiconductors with sturdy ceramic structures to preserve the heat variance between the two sides.

But the latest discovery that polymers also display thermoelectric behavior has encouraged a reconsideration of how to make the most of this method for better energy harvesting, including integration into wearable devices.

Derya Baran and her team at KAUST are helping to create self-driven devices using a conducting polymer comprising a combination of polystyrenesulfonate (PEDOT:PSS) and poly(3,4-ethylenedioxythiophene) chains.

Comparatively economical and simple to process for applications, including inkjet printing, PEDOT:PSS is one of the leading thermoelectric polymers owing to its ability to absorb efficiency-boosting additives called dopants.

Diego Rosas-Villalva, a researcher in Baran’s team, describes that thermoelectric PEDOT:PSS thin films are frequently exposed to dopants composed of strong acids. This process eliminates loose PSS chains to enhance polymer crystallinity and leaves behind particles that oxidize PEDOT chains to increase electrical conductivity.

We use nitric acid because it’s one of the best dopants for PEDOT. However, it evaporates rather easily, and this decreases the performance of the thermoelectric over time.

Diego Rosas-Villalva, Study Researcher, KAUST

Once the doping stage is finished, the PEDOT:PSS film has to endure a reverse process to neutralize or “dedope” certain conductive particles to advance thermoelectric power generation.

Characteristic dedopants include short hydrocarbons comprising positively charged amine groups. The KAUST team was analyzing a polymerized version of these amine chains, called ethoxylated polyethylenimine, when they observed an extraordinary effect—PEDOT:PSS films dedoped with polyethylenimine preserved double the quantity of thermoelectric power after one week compared with untreated samples.

The team’s examinations showed that polyethylenimine was successful in encapsulating PEDOT:PSS films to block the escape of nitric acid. Furthermore, this coating altered the thermoelectric polymer’s electronic properties to make it easier to generate energy from sources, including body heat.

We were not expecting that this polymer would improve the lifetime of the device, especially because it’s such a thin film—less than 5 nanometers. It’s been incorporated into other organic electronics before, but barely explored for thermoelectrics.

Diego Rosas-Villalva, Study Researcher, KAUST

Journal Reference:

Rosas-Villalva, D., et al. (2020) Enhanced thermoelectric performance and lifetime in acid-doped PEDOT:PSS films via work function modification. ACS Applied Energy Materials. doi.org/10.1021/acsaem.0c01511.