Nov 11 2020

For decades, silicon has been the driving force of electronics since it is more common, simple to process, and exhibits beneficial electronic properties.

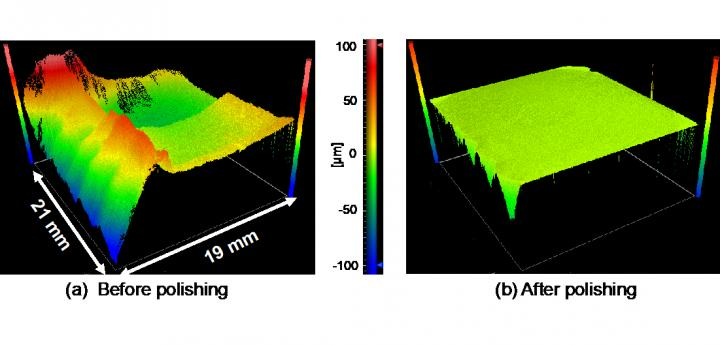

Shape of mosaic single-crystal diamond substrate before and after plasma-assisted polishing. Image Credit: Osaka University.

Shape of mosaic single-crystal diamond substrate before and after plasma-assisted polishing. Image Credit: Osaka University.

One drawback of silicon is that it tends to get damaged upon exposure to high temperatures, which restricts the speed of silicon-based electronics.

A possible alternative to silicon is single-crystal diamond. Although a single-crystal diamond wafer was recently fabricated by scientists, usual techniques of polishing the surface—a prerequisite for use in electronics—are a blend of slow and damaging.

Scientists from Osaka University and their collaborators polished a single-crystal diamond wafer to be almost atomically smooth. This process will help diamond replace at least a few of the silicon components in electronic devices. The results of the study were recently reported in Scientific Reports.

Diamond is the hardest of all substances and does not generally react with chemicals. When it is polished with an equally hard tool, its surface gets damaged and typical polishing chemistry tends to be slow.

In this research, the team mainly altered the quartz glass surface and further polished diamond with the help of modified quartz glass tools.

Plasma-assisted polishing is an ideal technique for single-crystal diamond. The plasma activates the carbon atoms on the diamond surface without destroying the crystal structure, which lets a quartz glass plate gently smooth away surface irregularities.

Nian Liu, Study Lead Author, Osaka University

Before it was polished, the single-crystal diamond contained several step-like features and was wavy on the whole, with an average root mean square roughness of 0.66 μm. Once it was polished, the topographical defects disappeared and the surface roughness was considerably less at 0.4 nm.

Polishing decreased the surface roughness to near-atomic smoothness. There were no scratches on the surface, as seen in scaife mechanical smoothing approaches.

Kazuya Yamamura, Study Senior Author, Osaka University

Moreover, the team found that the polished surface remained chemically unchanged. For instance, graphite was not detected, which indicates no damaged carbon. A very small amount of nitrogen from the original wafer preparation was the only impurity found.

Using Raman spectroscopy, the full width at half maximum of the diamond lines in the wafer were the same, and the peak positions were almost identical. Other polishing techniques show clear deviations from pure diamond.

Nian Liu, Study Lead Author, Osaka University

This research advancement could help achieve high-performance heat sinks and power devices based on single-crystal diamond. These technologies will considerably reduce the use of power and carbon input, while enhancing the performance, of future electronic devices.

Journal Reference:

Liu, N., et al. (2020) Damage-free highly efficient plasma-assisted polishing of a 20-mm square large mosaic single crystal diamond substrate. Scientific Reports. doi.org/10.1038/s41598-020-76430-6.