Dec 7 2020

Several fire incidents related to electric vehicle (EV) batteries have been reported recently. In contrast to batteries used in small mobile devices like smartphones, an EV’s battery pack includes hundreds of battery cells, and thus any instability could lead to major casualties and damage to property.

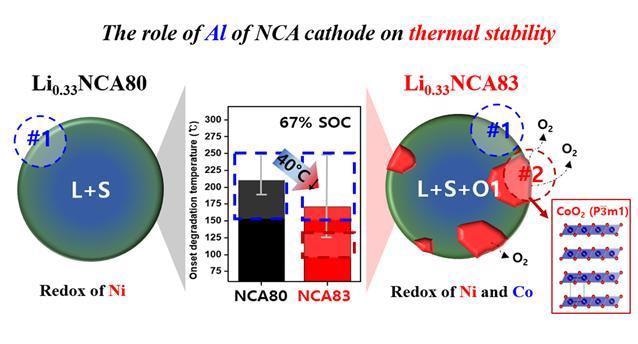

A graphical image depicting the role of an aluminum element that can reduce the risk of battery fires in NCA (nickel, cobalt, and aluminum), which is widely used as an anode material for electric vehicles. Image Credit: Korea Institute of Science and Technology (KIST).

A graphical image depicting the role of an aluminum element that can reduce the risk of battery fires in NCA (nickel, cobalt, and aluminum), which is widely used as an anode material for electric vehicles. Image Credit: Korea Institute of Science and Technology (KIST).

Besides several attempts to identify the cause of battery fires, researchers from Korea have created a new analysis technique to assess the thermal stability of EV batteries.

The Korea Institute of Science and Technology (KIST) has reported that a research group headed by Dr Wonyoung Chang of the KIST Center for Energy Storage Research and Dr Seung Min Kim of the Carbon Composite Materials Research Center of the Jeonbuk Branch developed a real-time analysis platform to assess the thermal stability of the cathode material of a battery.

The technique involves using a transmission electron microscope, which helps pinpoint the thermal degradation mechanism based on the variation in the chemical composition of the high-nickel cathode material for EVs.

The cathode material of an EV battery is one of the crucial factors that govern the capacity of the battery and thus the range of driving. The cathode is made by combining different metals like cobalt, nickel, and aluminum or manganese, nickel, and cobalt, based on the designated mixing ratio. Scientists from various companies and academic circles are making efforts to find an ideal composition ratio to improve the driving range of EVs.

The cathode material consists of nickel, and the nickel content and the capacity are positively correlated. Moreover, nickel is cheaper when compared to cobalt, and thus, the addition of more nickel effectively reduces the unit cost of an EV battery.

But a detrimental disadvantage of nickel is that it affects the stability of the battery as it tends to react easily with the external environment. The nickel content of the cathode material used for the third-generation EVs, which are now being developed, has been increased up to or greater than 80%, and the resulting decline in stability must be enhanced to ensure safety.

Battery fires are mainly triggered by a vigorous exothermic reaction between the flammable liquid electrolytes and the charged oxide-based cathode material.

Therefore, the KIST research team paid attention to the surface of the cathode in contact with the electrolytes and used a range of transmission electron microscopy methods (electron diffraction, electron energy loss spectroscopy, etc.) to closely observe and analyze the cathode’s crystal structure and the chemical variations in the constituents caused by an increase in the temperature.

Thus, the researchers could pinpoint the cause of decrease in thermal stability of the battery based on the chemical composition of the NCA (nickel, cobalt, aluminum) cathode material and the role played by the constituent elements to ensure the battery’s safety.

The KIST researchers found that an increase in the amount of nickel than the aluminum content in the NCA cathode material enhances the battery capacity but considerably reduces the thermal stability in the upper charging limit (67% reaction of total lithium ions).

An investigation revealed that aluminum did not take part in the redox reaction, and this results in the formation of a new phase (O1 phase) that can decrease the thermal stability when the battery is charged. The surface of the new unstable phase was identified to be the eventual cause of decreased thermal stability.

There have been a series of EV fires worldwide, and the source of the fire, in many cases, was the battery. This study confirmed the importance of a chemical composition design that ensures thermal stability in developing high-performance cathode materials.

Dr Wonyoung Chang, Korea Institute of Science and Technology

According to Dr Seung Min Kim from the Jeonbuk Branch of KIST, “Ensuring thermal stability of the cathode material where exothermic reactions begin is key to popularizing EVs. The advanced analysis techniques developed in this study will help determine the effects of elements in trace amounts and in turn lead to the development of high-performance cathode materials that are guaranteed to be safe.”

Journal Reference:

Jo, E., et al. (2020) Different thermal degradation mechanisms: Role of aluminum in Ni-rich layered cathode materials. Nano Energy. doi.org/10.1016/j.nanoen.2020.105367.