Jan 27 2021

Researchers from the Tokyo Institute of Technology (Tokyo Tech) have demonstrated through experiments that a clean electrode/electrolyte interface is crucial to achieve high-capacity solid-state lithium batteries.

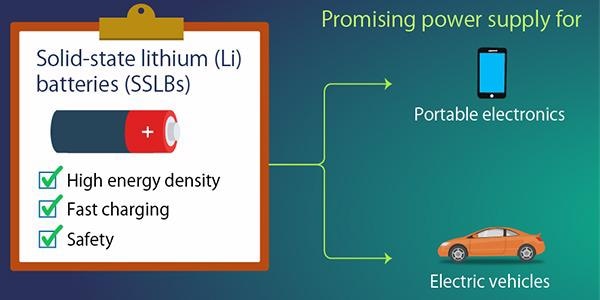

The benefits of solid-state lithium batteries. Image Credit: Hideyuki Kawasoko et al.

The benefits of solid-state lithium batteries. Image Credit: Hideyuki Kawasoko et al.

The study was performed in collaboration with Tohoku University, the National Institute of Advanced Industrial Science and Technology, and the Nippon Institute of Technology.

The researchers’ findings could lay the basis for enhanced battery designs with better stability, capacity, and safety for both electric vehicles and mobile devices.

Liquid lithium-ion batteries can be found everywhere. In fact, they are found in many day-to-day mobile devices. While liquid lithium-ion batteries have a fair share of benefits, they carry profound risks as well. In the recent past, this has become evident to the public when reports were circulated about smartphones bursting into flames. This was due to faulty designs that made the liquid electrolyte of the battery to leak and burst into flames.

Other drawbacks, like capacity, durability, and fabrication cost, made the investigators to focus on a different technology known as solid-state lithium batteries (SSLBs). SSLBs include a solid electrolyte and solid electrodes that exchange lithium (Li) ions at the time of charge-discharge cycles. Improved safety and higher energy density make SSLBs very robust sources.

But several technical challenges still exist that prevent the commercialization of SSLBs. For the present study, scientists carried out a set of experiments and gained a better understanding that could take the performance of the SSLBs to the next level.

LiNi0.5Mn1.5O4 (LNMO) is a promising material for the positive electrode of SSLBs because it can generate comparatively higher voltages. In this study, we showed battery operations at 2.9 and 4.7 V, and simultaneously achieved large capacity, stable cycling, and low resistance at the electrolyte/electrode interface.

Taro Hitosugi, Study Lead and Professor, Tokyo Institute of Technology

Prior studies had implied that generating a clean electrolyte/electrode interface was crucial to realize rapid charging and low interface resistance in LNMO-based SSLBs. Moreover, researchers observed that Li ions spontaneously shifted from Li3PO4 (LPO) electrolyte to the LNMO layer after they were fabricated and formed a Li2Ni0.5Mn1.5 O4 (L2NMO) phase in LNMO with unfamiliar distribution and effect on the performance of the battery.

The researchers explored the appearance of the L2NMO phase, investigating the variations in the crystalline structure between the L2NMO and Li0Ni0.5 Mn1.5 O4 (L0NMO) phases during charge-discharge cycles. The team also analyzed the preliminary distribution of L2NMO at clean LPO/LNMO interfaces produced in a vacuum, and also the impact of thickness of the electrode.

Remarkably, the clean interface streamlined the deintercalation and intercalation of Li during the charge-discharge cycle of the SSLBs. Consequently, the capacity of SSLBs with a clean interface was twice that of traditional LNMO-based batteries. The study also marked the initial stable reversible reactions that were seen between the L2NMO and L0NMO phases in SSLBs.

Our findings indicate that the formation of a contamination-free, clean LPO/LNMO interface is key to increasing the capacity of SSLBs while ensuring low interface resistance for fast charging.

Hideyuki Kawasoko, Study Lead Author and Assistant Professor, Tohoku University

Apart from mobile devices, SSLBs could be used in electric cars, for which price and the durability of batteries serve as significant barriers for extensive commercialization. The study results offer crucial insights for upcoming SSLB designs and provide the basis for a migration from fossil fuels and toward more environmentally-friendly methods of transportation. The advent of SSLBs is something to look forward to.

Journal Reference

Kawasoko, H., et al. (2021) Clean Solid–Electrolyte/Electrode Interfaces Double the Capacity of Solid-State Lithium Batteries. ASC Applied Materials & Interfaces. doi.org/10.1021/acsami.0c21586.